TRAINING COURSES

📚 Courses We Offer 📚

Process & Chemical Engineering

Explore our expertly curated courses designed to elevate your skills and knowledge.

- PE0390 : Distillation-Column Operation, Control & Troubleshooting

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- PE0531 : Flare, Blowdown & Pressure Relief Systems

- Date : Jan 06 - Jan 10 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

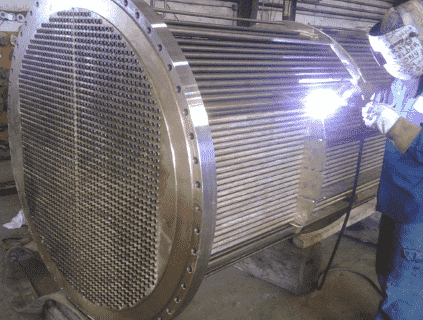

- PE0382 : Heat Exchangers & Fired Heaters

- Date : Jan 13 - Jan 17 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

- PE0102 : Certified Process Plant Operator Program

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- PE0987 : De-Sulfurization Technology

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- PE0221 : Operation of Process Equipment: Fired Heaters, Air Coolers, Heat Exchangers, Pumps, Compressors, Crude Desalter, Pressure Vessels & Valves

- Date : Jan 20 - Jan 24 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

- PE0105 : Process Plant Optimization, Revamping & Debottlenecking

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

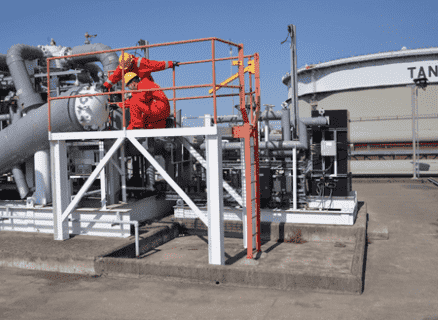

- PE0010 : Oil Movement, Storage & Troubleshooting

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- PE0640 : Troubleshooting Process Operations

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- PE0310 : Gas Sweetening & Sulphur Recovery

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- PE0115 : Process Plant Performance & Efficiency

- Date : Feb 10 - Feb 14 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

- PE0910 : Refinery Production Operations & Petroleum Products

- Date : Feb 16 - Feb 20 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- PE0912 : Advanced Refinery Operations, Plants Process & Troubleshooting

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- PE0358 : Aspen HYSYS (EHY101 EHY202)

- Date : Jan 13 - Jan 16 2025 / 4 Days

- Location : Al Khobar, KSA

- Course Details

- PE0240 : Liquid Bulk Cargo Handling: CRUDE OIL & LNG: Storage, Separation, Loading, Unloading, Marine Operations, Dehydration, Desalting, Measurement and Calculations

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- PE0909(PE8) : Oil & Gas Pipeline Troubleshooting & Operation Problem Solving

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- PE0115 : Process Plant Performance & Efficiency

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- PE0105 : Process Plant Optimization, Rehabilitation, Revamping, Debottlenecking & Continuous Improvement

- Date : Nov 10 - Nov 14 2025 / 5 Days

- Location : Abu Dhabi, UAE

- Course Details

- PE0105 : Process Plant Optimization, Rehabilitation, Revamping, Debottlenecking & Continuous Improvement

- Date : May 04 - May 08 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- PE0390 : Distillation-Column Operation, Control & Troubleshooting

- Date : Oct 12 - Oct 16 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- PE0390 : Distillation-Column Operation, Control & Troubleshooting

- Date : Jul 21 - Jul 25 2025 / 5 Days

- Location : Abu Dhabi, UAE

- Course Details

- PE0390 : Distillation-Column Operation, Control & Troubleshooting

- Date : Apr 27 - May 01 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- PE0010 : Oil Movement, Storage & Troubleshooting

- Date : Feb 23 - Feb 27 2025 / 5 Days

- Location : Cairo, Egypt

- Course Details

- PE0020 : Process Equipment Design, Sizing, Selection, Applications, Operation & Troubleshooting

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Cairo, Egypt

- Course Details

Process Chemical Engineering by Haward Technology Middle East

Master Complex Engineering Challenges with the World's Leading Technical Training Provider

Haward Technology Middle East specializes in delivering world-class technical training that empowers engineers with the knowledge, skills, and confidence to perform efficiently in high-stakes environments across the oil, gas, process, power, and petrochemical sectors.

Why Choose Haward Technology Middle East?

Haward Technology Middle East, the world’s largest accredited technical training provider, offers engineers worldwide a training experience that stands above the rest. Our training is driven by a clear mission: to bridge the gap in engineering knowledge between the West and the Middle East.

We offer over 8,000 courses across all engineering disciplines, led by 800+ expert instructors, many of whom are registered inventors and patent holders in their fields. This gives you direct access to real-world knowledge, tested methodologies, and breakthrough innovations.

Specialized Petroleum Engineering Courses Online

We understand the unique demands of the oil and gas sector, which is why we offer Petroleum Engineering courses online for maximum flexibility and accessibility. These online programs are created to match international industry standards, blending theoretical knowledge with practical insight.

No matter if you're a field operator, a process engineer, or a project manager, these courses are tailored to expand your understanding of reservoir management, drilling operations, well performance analysis, and enhanced oil recovery techniques.

Our online courses include:

● Introduction to Petroleum Engineering

● Advanced Oil and Gas Production Techniques

● Offshore Drilling and Safety Systems

● Petroleum Refining Operations

Each course is led by experienced instructors who bring real-world expertise directly to your screen.

Earn Your Petroleum Engineering Certificate Online

For professionals looking to strengthen their credentials, Haward Technology Middle East offers an industry-recognized Petroleum Engineering certificate online. This certification proves your expertise and shows that you stay current with the latest technologies and industry practices.

Designed for working professionals, our certificate programs are structured to be flexible, interactive, and comprehensive, making it easier to study at your own pace without compromising work commitments.

The certification also opens up new career opportunities in:

● Refining and petrochemical operations

● Reservoir and production management

● Energy sector consulting

● Process plant engineering and troubleshooting

Certification Courses for Chemical Engineers

At Haward Technology Middle East, we believe continuous professional development is the key to long-term success. Our certification courses for chemical engineers are structured to build core competencies while advancing your practical understanding of chemical processes and system designs. Key focus areas include:

● Heat and mass transfer

● Chemical reaction engineering

● Process safety and HAZOP

● Distillation and separation technologies

● Piping and instrumentation design

These intensive certification courses are suitable for:

● New graduates looking to break into the industry

● Experienced engineers seeking to upgrade their skills

● Professionals preparing for leadership roles in technical departments

Each course includes a blend of lectures, case studies, practical exercises, and simulator-based learning to help participants apply what they learn in real-time settings.

Refinery Training Courses with Real-World Applications

Our refinery training courses are engineered to meet the rigorous demands of downstream operations. Our instructors deliver practical content that covers everything, including basic refining principles, complex catalytic cracking, and hydrotreating processes. Popular topics include:

● Refinery Process Optimization

● Troubleshooting in Oil Refineries

● Crude Oil Distillation and Treatment

● Energy Conservation in Refineries

With access to simulation software, real-life case studies, and interactive group workshops, participants walk away with applicable insights that can be implemented directly on the job. These courses are perfect for professionals working in:

● Process operation and control

● Engineering and design departments

● Refinery maintenance and reliability

Petrochemical Plant Training Courses to Build Industry Expertise

Chemical engineers involved in the production of polymers, fertilizers, solvents, and synthetic materials can benefit greatly from our Petrochemical Plant training courses. These programs are specifically crafted to match the dynamic nature of the petrochemical industry.

Training Methodology Designed for Maximum Impact

Our focus goes beyond teaching; we deliver training that makes a lasting impact. Our training methodology includes:

● Instructor-led Lectures

● Practical Workshops

● Hands-on Exercises

● Case Studies

● Software & Hardware Simulations

● Video-Based Learning

This interactive approach is to make sure participants don’t just understand engineering concepts, they know how to use them effectively in real-world scenarios.

Our training programs also include periodic assessments and group presentations to reinforce learning and enhance collaboration among peers.

Learn from Experts Who Shape the Industry

Our instructors are recognized leaders and innovators in their respective disciplines. Many are published authors, patent holders, and senior consultants to some of the world’s biggest oil, gas, and chemical companies.

They bring with them decades of hands-on experience, so you learn not just from books, but from the field itself.

Start Advancing Your Career Today

Looking to strengthen your technical skills and gain global recognition? Check out our online Petroleum Engineering courses, earn a certified Petroleum Engineering qualification, or sign up for our certification programs designed for chemical engineers. We also offer specialized Refinery training courses and Petrochemical Plant training courses designed for real-world results.

Visit our website to browse courses or speak with our team for personalized guidance. Your engineering career deserves first-class training, and that's exactly what we deliver.