TRAINING COURSES

📚 Courses We Offer 📚

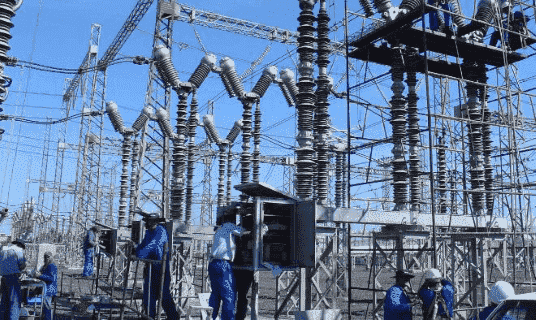

Electrical & Power Engineering

Explore our expertly curated courses designed to elevate your skills and knowledge.

- EE0050S3 : High and Medium Voltage Substation Design, Testing and Maintenance

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- EE0421 : Electrical Transformers & Switchgears Faults, Inspection, Testing, Maintenance & Troubleshooting

- Date : Feb 23 - Feb 27 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

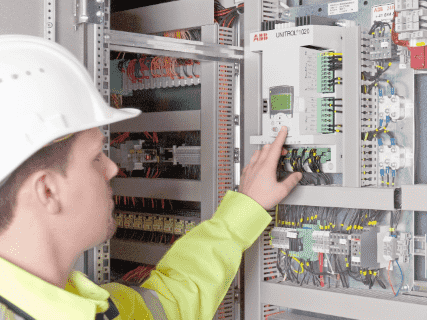

- EE0136 : Advanced ABB VSD Controllers

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- EE0625 : Certified High Voltage Electrical Safety (IEC, OSHA, NFPA & EN Standards)

- Date : Nov 02 - Nov 06 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- EE0625 : Certified High Voltage Electrical Safety (IEC, OSHA, NFPA & EN Standards)

- Date : Aug 04 - Aug 08 2025 / 5 Days

- Location : Abu Dhabi, UAE

- Course Details

- EE0250 : Electrical Distribution Systems - Fundamental

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- EE0625 : Certified High Voltage Electrical Safety (IEC, OSHA, NFPA & EN Standards)

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- EE0050 : HV/MV Substation Design, Installation, Commissioning, Testing, Operation, Control & Maintenance

- Date : Feb 23 - Feb 27 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- EE0050 : HV/MV Substation Design, Installation, Commissioning, Testing, Operation, Control & Maintenance

- Date : Jul 27 - Jul 31 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- EE0421 : Electrical Transformers & Switchgears Faults, Inspection, Testing, Maintenance & Troubleshooting

- Date : Nov 16 - Nov 20 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- EE0764 : VSD, Motors, SCADA, FAT & Electrical Safety

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- EE0901 : Operation and Maintenance for MV Switchgear

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- EE0901 : Operation and Maintenance for MV Switchgear

- Date : Oct 26 - Oct 30 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- EE0660 : Earthing, Bonding, Lightning & Surge Protection of Electrical & Electronic Systems and Equipment

- Date : Jan 20 - Jan 24 2025 / 5 Days

- Location : Kuala Lumpur, Malaysia

- Course Details

- EE0259 : Bulk & SUB Meter Complaints

- Date : May 25 - May 29 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- EE0709 : Electrical Fault Finding Procedure

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- EE0625 : Certified High Voltage Electrical Safety (IEC, OSHA, NFPA & EN Standards)

- Date : Jan 06 - Jan 10 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- EE0050 : HV/MV Substation Design, Installation, Commissioning, Testing, Operation, Control & Maintenance

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- EE1030 : Certified Electrical Safety Compliance Professional (NFPA - CESCP Exam Preparation Training)

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- EE1002 : Classification of Locations for Electrical Installations at Petroleum Facilities (API 500/ API 505/ API RP 14FZ)

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- EE0854 : ABB REF 542 & 545 for Modern Multifunction Protection & Switchgear Control

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- EE0200 : Practical Troubleshooting of Electrical Equipments & Control Circuits

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

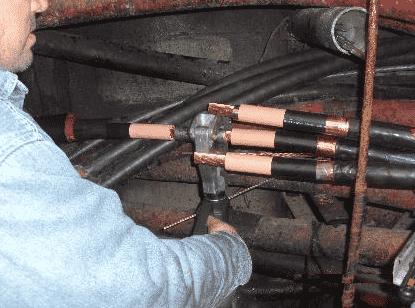

- EE0763 : 115KV Cable Splicing Training and Certification

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- EE0295 : Variable Frequency Drives (VFD)

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

Electrical Power Engineering Training by Haward Technology Middle East

Sharpen Your Engineering Skills with Industry-Leading Technical Programs

Haward Technology Middle East offers advanced Electrical Power Engineering training designed for professionals working in high-risk, high-performance sectors like oil, gas, power, petrochemicals, and heavy industries. Our programs give engineers the tools and technical knowledge needed to handle complex systems with efficiency, accuracy, and safety.

What Sets Haward Technology Middle East Apart in Technical Training?

As the world’s largest accredited provider of technical training, Haward Technology Middle East delivers practical, experience-driven learning to engineers around the globe. Our mission is simple: bridge the technical skills gap by offering high-quality programs backed by real-world expertise.

With over 8,000 courses across multiple disciplines and a faculty of more than 800 industry veterans, our training equips professionals with insights that can only come from hands-on experience and innovation.

Flexible Electrical Engineer Courses Online

To meet the evolving needs of today’s workforce, we offer electrical engineer courses online that combine global standards with local relevance. These remote learning options are ideal for engineers who want to upskill without pausing their careers.

Each course is designed to provide both foundational knowledge and advanced application. No matter if you're involved in power distribution, system design, or maintenance planning, these programs give you the tools to work smarter and safer.

Popular course topics include:

● Fundamentals of Electrical Power Systems

● Substation Design and Operation

● Power System Protection and Relays

● High Voltage Engineering and Safety Practices

Courses are delivered by experts who understand the demands of the electrical industry and offer practical solutions based on real-world experience.

Recognized Certification Courses for Electrical Engineers

Professionals seeking to verify their skills and enhance their qualifications can benefit from our certification courses for electrical engineers. These programs offer comprehensive coverage of key topics and provide industry-recognized certification upon completion.

This certification signals to employers and clients that you understand the latest technologies and can apply them effectively in your field. Programs are built for flexibility, so you can study at your own pace while still meeting work commitments.

Participants commonly move into roles such as:

● Electrical Design Engineers

● Power System Analysts

● Control and Instrumentation Specialists

● Energy Consultants

The certificate also helps professionals meet compliance standards and improve their chances for promotions and leadership roles.

In-Depth Electrical Engineer Training Courses

Our electrical engineer training courses offer a balanced mix of theory and practice, covering everything, including system fundamentals and advanced troubleshooting techniques. With a focus on safety, energy efficiency, and reliability, these programs are valuable for engineers at every stage of their careers. Core focus areas include:

● Transformer Operation and Maintenance

● Generator Control Systems

● Electrical Load Forecasting

● Fault Analysis and Risk Reduction

● SCADA and Smart Grid Technologies

These courses are ideal for:

● Fresh graduates entering the power sector

● Mid-level engineers expanding their skill set

● Senior professionals preparing for project management or advisory roles

Every course includes lectures, technical workshops, simulations, and case studies to strengthen understanding and practical application.

Practical Electrical Training Courses Built for Industry

Our electrical training courses are shaped by the needs of industries that rely on high-performance electrical systems. These programs provide hands-on knowledge for real scenarios, helping engineers not just solve problems, but prevent them.

Key areas covered include:

● Electrical Safety and Arc Flash Analysis

● Power Factor Correction

● Cable Selection and Installation Standards

● Energy Audits and System Efficiency

● Emergency Power Systems and UPS

The courses benefit professionals involved in:

● Plant maintenance and operations

● Engineering design and construction

● Utility system planning

● Industrial automation

With access to simulators, real-world data, and collaborative group sessions, engineers walk away ready to apply what they’ve learned.

Our Hands-On Training Method: More Than Just Theory

Haward Technology Middle East goes beyond classroom instruction. Our training combines real-life examples, expert-led sessions, and advanced tools to give engineers practical, usable knowledge. Our approach includes:

● Detailed Lectures

● Interactive Workshops

● Hands-On Exercises

● Software & Hardware Simulations

● Case-Based Problem Solving

● Multimedia & Video Demonstrations

Each course is structured to help participants understand how to apply their learning directly in operational environments. Group discussions and assessments are also integrated to boost knowledge retention and peer learning.

Learn from Top Professionals in the Power Sector

Our instructors are not just trainers; they’re pioneers in their fields. Many hold patents, lead industry research, or serve as consultants to major international energy companies.

With years of on-site experience and academic expertise, they provide participants with a clear understanding of both theoretical principles and technical realities.

Take the Next Step in Your Engineering Career

Looking to move forward in your profession? Haward Technology Middle East offers a wide range of opportunities to do just that. Enroll in electrical engineer courses online, earn credentials through our certification courses for electrical engineers, or build practical expertise with our electrical engineer training courses and electrical training courses.

Visit our website to explore programs or get in touch for tailored advice. With Haward Technology Middle East, you're not just learning, you’re building a smarter, stronger future in electrical engineering.