TRAINING COURSES

📚 Courses We Offer 📚

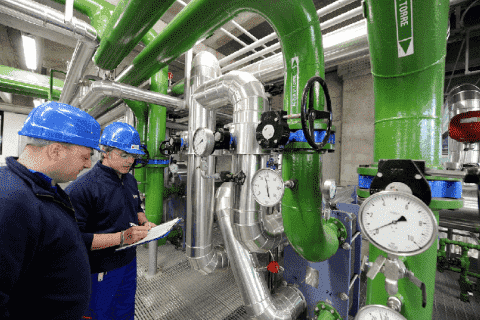

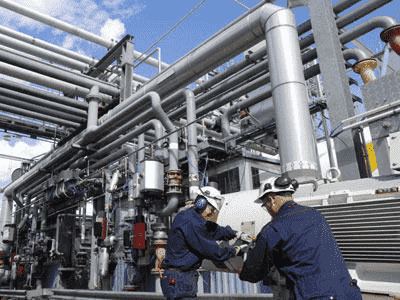

Maintenance, Reliability & Rotating Equipment Engineering

Explore our expertly curated courses designed to elevate your skills and knowledge.

- RE0010 : Certified Maintenance Auditor (CMA)

- Date : Sep 21 - Sep 25 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- RE0628 : Certified Machinery Lubrication Technician (MLT) Level - I: ICML-MLT Certification

- Date : Jun 22 - Jun 24 2025 / 3 Days

- Location : Dubai, UAE

- Course Details

- RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- RE0212 : Excellence in Maintenance & Reliability Management

- Date : Feb 02 - Feb 06 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0096 : Advanced Inspection & Performance Evaluation of Rotating Equipment including Turbine Maintenance

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0946 : Material Handling, Control and Spare Parts Movements

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0097 : Rotating Equipment Fundamentals

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- RE0141 : Certified Machinery Failure Analysis, Vibration & Predictive Maintenance: Machinery Diagnostics & Root Cause Failure Analysis to Improve Equipment Performance

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

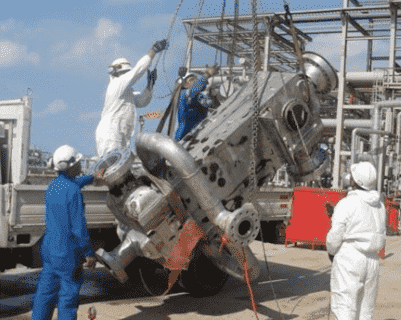

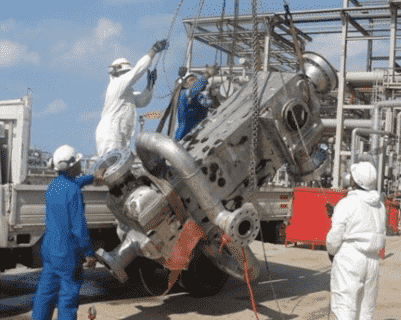

- RE0930 : Process Plant Shutdown, Turnaround & Troubleshooting

- Date : Apr 06 - Apr 10 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- RE0930 : Process Plant Shutdown, Turnaround & Troubleshooting

- Date : Sep 28 - Oct 02 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date : Feb 02 - Feb 06 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0128 : Maintenance of Finfans Coolers

- Date : Apr 13 - Apr 17 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date : Dec 14 - Dec 18 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0128 : Maintenance of Finfans Coolers

- Date : Aug 24 - Aug 28 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0019 : Certified Maintenance & Reliability Technician (CMRT) (SMRP Exam Preparation Training)

- Date : Jun 15 - Jun 19 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0617 : Certified Machine Lubricant Analyst (MLA) Level - I - ISO 18436-4/ICML Certification

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0617 : Certified Machine Lubricant Analyst (MLA) Level - I - ISO 18436-4/ICML Certification

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0190 : Practical Machinery Vibration Monitoring, Analysis & Predictive Maintenance: Vibration Techniques

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0030 : Rotating Equipment Reliability Optimization

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0225 : Certified Maintenance Planner (CMP)

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0300 : Bently Nevada 3500 Operation & Maintenance

- Date : Jan 13 - Jan 17 2025 / 5 Days

- Location : Abu Dhabi, UAE

- Course Details

- RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- RE0761 : Rotating Equipment Selection, Operation, Troubleshooting & Effective Predictive Maintenance

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0626 : Certified Machine Lubricant Analyst (MLA) Level-II ISO 18436-4/ICML Certification

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Doha, Qatar

- Course Details