TRAINING COURSES

📚 Courses We Offer 📚

Mechanical Engineering

Explore our expertly curated courses designed to elevate your skills and knowledge.

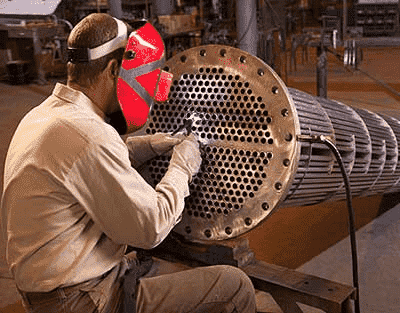

- ME0062 : Heat Exchanger Operation, Maintenance & Repair

- Date : Jan 06 - Jan 10 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

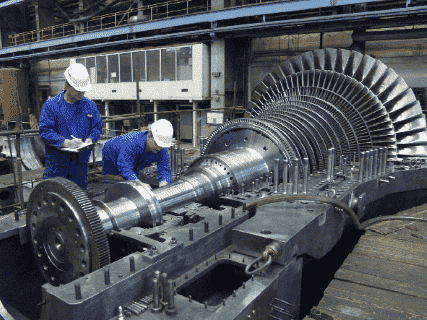

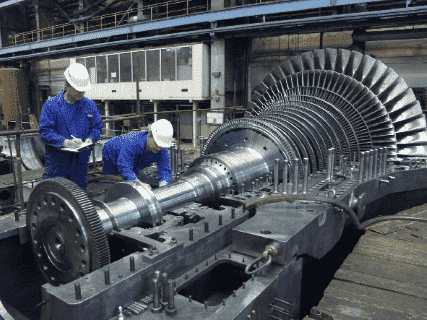

- ME0015 : Centrifugal Compressor & Steam Turbine Design, Performance, Operation, Maintenance & Troubleshooting

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

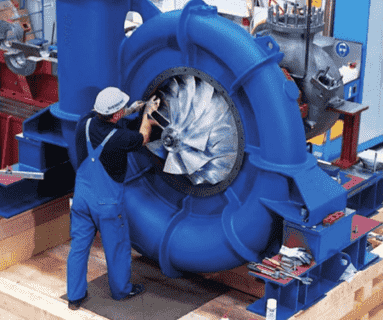

- ME0615 : Operation, Maintenance & Troubleshooting of Pumps & Compressors

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0447 : Rotating Equipment: Pumps, Turbines & Compressors Technology: Design, Selection, Operation, Control, Inspection, Maintenance & Troubleshooting

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

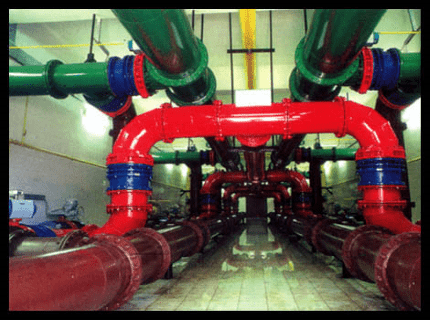

- ME0630 : The Layout of Piping Systems & Process Equipment

- Date : Feb 03 - Feb 07 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

- ME0045J1 : Design, Fabrication & Testing of ASME VIII Pressure Vessels

- Date : Feb 02 - Feb 06 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0089 : Steam Boilers Operation, Maintenance and Control System

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- ME0075 : Control Valves & Actuators

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- ME0098 : Pump Technology

- Date : Feb 16 - Feb 20 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- ME0527 : Steam Boilers Operation & Maintenance

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- ME0397 : Practical Pump & Valve Technology: Selection, Operation, Control, Maintenance & Troubleshooting

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- ME0122 : Valves, Safety Relief Valves, Strainers & Steam Traps

- Date : Feb 16 - Feb 20 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- ME0062 : Heat Exchanger Design, Operation, Performance, Inspection, Maintenance & Repair

- Date : Dec 21 - Dec 25 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- ME0062 : Heat Exchanger Design, Operation, Performance, Inspection, Maintenance & Repair

- Date : Jul 20 - Jul 24 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- ME0489 : Inspect and Maintain Safeguarding Vent and Relief Systems

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0078(AD6) : Maintain and Test Control Valves

- Date : Feb 03 - Feb 07 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

- ME0878(KJ1) : Valve Maintenance

- Date : Feb 17 - Feb 21 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

- PM0542 : PMI Professional in Business Analysis (PMI-PBA) PMI Exam Preparation Training

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- ME0590 : Diesel Engine Maintenance & Troubleshooting

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0015 : Centrifugal Compressor & Steam Turbine Design, Performance, Operation, Maintenance & Troubleshooting

- Date : Apr 20 - Apr 24 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- ME0020 : Certified Boiler Operation, Control, Maintenance & Troubleshooting

- Date : Feb 02 - Feb 06 2025 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0027 : Centrifugal Pump Selection, Construction, Operation, Maintenance, Repair & Troubleshooting

- Date : Feb 23 - Feb 27 2025 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0045 : ASME VIII Pressure Vessel Design, Fabrication & Testing

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0172 : INDUSTRIAL EQUIPMENT & TURBOMACHINERY: Pumps, Compressors, Turbines & Motors: Selection, Sizing, Applications, Operation, Diagnostic Testing, Troubleshooting, Maintenance & Failure Analysis

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Cairo, Egypt

- Course Details