TRAINING COURSES

📚 Courses We Offer 📚

Maintenance, Reliability & Rotating Equipment Engineering

Explore our expertly curated courses designed to elevate your skills and knowledge.

- RE0010 : Certified Maintenance Auditor (CMA)

- Date : Sep 21 - Sep 25 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- RE0628 : Certified Machinery Lubrication Technician (MLT) Level - I: ICML-MLT Certification

- Date : Jun 22 - Jun 24 2025 / 3 Days

- Location : Dubai, UAE

- Course Details

- RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- RE0212 : Excellence in Maintenance & Reliability Management

- Date : Feb 02 - Feb 06 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0096 : Advanced Inspection & Performance Evaluation of Rotating Equipment including Turbine Maintenance

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0946 : Material Handling, Control and Spare Parts Movements

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0097 : Rotating Equipment Fundamentals

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- RE0141 : Certified Machinery Failure Analysis, Vibration & Predictive Maintenance: Machinery Diagnostics & Root Cause Failure Analysis to Improve Equipment Performance

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- RE0930 : Process Plant Shutdown, Turnaround & Troubleshooting

- Date : Apr 06 - Apr 10 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- RE0930 : Process Plant Shutdown, Turnaround & Troubleshooting

- Date : Sep 28 - Oct 02 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date : Feb 02 - Feb 06 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0128 : Maintenance of Finfans Coolers

- Date : Apr 13 - Apr 17 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date : Dec 14 - Dec 18 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0128 : Maintenance of Finfans Coolers

- Date : Aug 24 - Aug 28 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0019 : Certified Maintenance & Reliability Technician (CMRT) (SMRP Exam Preparation Training)

- Date : Jun 15 - Jun 19 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0617 : Certified Machine Lubricant Analyst (MLA) Level - I - ISO 18436-4/ICML Certification

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0617 : Certified Machine Lubricant Analyst (MLA) Level - I - ISO 18436-4/ICML Certification

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0190 : Practical Machinery Vibration Monitoring, Analysis & Predictive Maintenance: Vibration Techniques

- Date : Jan 05 - Jan 09 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0030 : Rotating Equipment Reliability Optimization

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0225 : Certified Maintenance Planner (CMP)

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- RE0300 : Bently Nevada 3500 Operation & Maintenance

- Date : Jan 13 - Jan 17 2025 / 5 Days

- Location : Abu Dhabi, UAE

- Course Details

- RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- RE0761 : Rotating Equipment Selection, Operation, Troubleshooting & Effective Predictive Maintenance

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- RE0626 : Certified Machine Lubricant Analyst (MLA) Level-II ISO 18436-4/ICML Certification

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

Maintenance, Reliability & Rotating Equipment Engineering Training for Industry Professionals

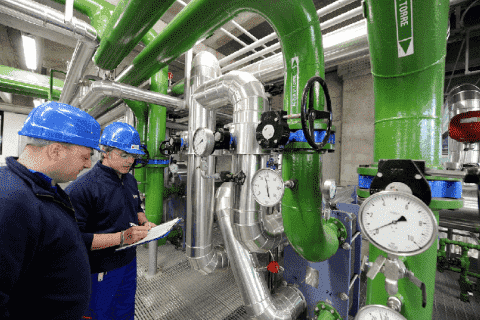

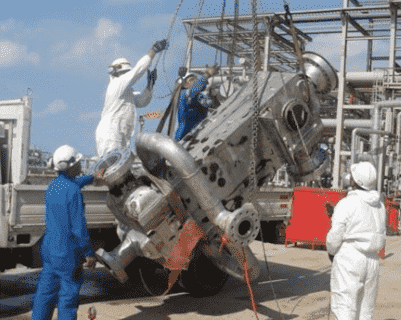

Keeping industrial operations running smoothly depends on the reliability and performance of rotating machinery. Pumps, compressors, turbines, and other critical equipment are the heart of process industries, and any downtime can lead to major production losses. That’s why professionals across oil and gas, petrochemical, power, and manufacturing sectors invest in advanced training to strengthen their skills in maintenance and reliability.

Understanding the Importance of Equipment Reliability

Reliability isn’t just about fixing problems; it’s about preventing them. In industries where every second of uptime matters, mastering the science of equipment reliability helps professionals identify potential failures early, reduce maintenance costs, and boost overall plant performance. Through a reliability engineering training course, engineers and maintenance specialists gain the expertise to apply predictive maintenance techniques and improve long-term operational efficiency.

This training bridges theory and practical knowledge, giving participants the tools to analyze failure data, apply reliability-centered maintenance (RCM) strategies, and use condition monitoring for continuous improvement.

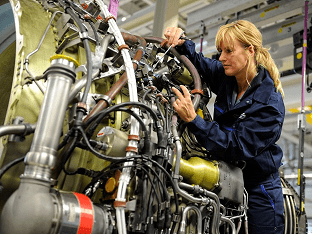

Building Expertise in Rotating Equipment Maintenance

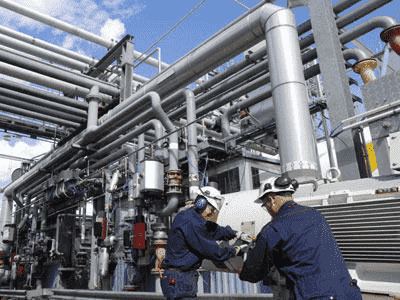

Rotating machines are among the most vital assets in any plant operation. Their complexity demands specialized knowledge for both maintenance and troubleshooting. A rotating equipment maintenance training program equips engineers and technicians to handle real-world challenges such as vibration analysis, alignment issues, bearing failures, and lubrication management.

What Participants Learn

- Principles of rotating machinery operation

- Common causes of mechanical failure and preventive actions

- Techniques for vibration analysis and dynamic balancing

- Performance testing and reliability improvement strategies

Through hands-on exercises and real-life case studies, participants learn to extend equipment life and reduce unplanned outages, skills that directly impact productivity and cost efficiency.

Advancing Your Career Through Reliability Engineering

For professionals seeking career growth, obtaining a reliability engineering certification opens new doors. This qualification signals a strong understanding of predictive maintenance, asset management, and risk assessment, skills that are highly valued in energy, chemical, and industrial sectors.

The certification also introduces participants to tools like root cause analysis (RCA), Failure Mode and Effects Analysis (FMEA), and reliability block diagrams. These approaches support data-driven decision-making and continuous process improvement, helping engineers move into more strategic maintenance and asset management roles.

Mastering the Fundamentals of Rotating Equipment Engineering

A rotating equipment engineering course goes beyond basic maintenance; it dives into the design, operation, and optimization of key machinery. Participants explore how these systems interact in complex industrial setups and how to maintain peak efficiency under demanding operating conditions.

Key Focus Areas

- Mechanical design principles for rotating machinery

- Material selection and stress analysis

- Fluid dynamics and thermal performance

- System integration in industrial processes

Such training benefits mechanical and process engineers who want to deepen their technical understanding and contribute to performance optimization at the design and operational stages.

Practical Skills for Real-World Application

The combination of maintenance and reliability disciplines offers professionals a complete understanding of equipment performance throughout its lifecycle. These courses teach how to maintain a balance between operational efficiency and safety.

Hands-on sessions and workshops help participants apply analytical techniques in real-time scenarios, interpret condition-monitoring data, and plan maintenance schedules based on asset health rather than fixed intervals. This practical exposure is vital in industries where downtime translates directly into lost revenue.

A Learning Path That Fits Diverse Engineering Fields

Professionals working in different areas of engineering can also benefit from these programs. For instance, those pursuing chemical engineering courses can integrate reliability principles into process optimization. Whereas those thinking about advancing their careers through electrical engineering courses online can understand how motor-driven systems impact the performance of rotating machinery.

The interdisciplinary approach encourages collaboration among mechanical, electrical, and process engineers for a comprehensive understanding of plant operations.

Why Training in Maintenance and Reliability Matters

In today’s competitive industrial landscape, companies seek professionals who can think ahead, those capable of anticipating potential issues and implementing solutions before problems occur. Trained reliability engineers and maintenance specialists contribute to safer, more efficient, and cost-effective operations.

Effective maintenance practices not only reduce breakdowns but also minimize energy consumption and improve equipment lifespan. By understanding how to predict failures and optimize performance, participants become key assets in achieving sustainable production goals.

Who Should Attend

This program is ideal for:

- Maintenance and reliability engineers

- Mechanical and process engineers

- Plant supervisors and maintenance planners

- Technical professionals involved in equipment management and performance analysis

Participants leave the course ready to apply modern techniques for inspection, maintenance planning, and reliability improvement within their organizations.

Join the Next Training Session

For professionals looking to strengthen their expertise in rotating machinery, reliability, and asset management, these programs offer a structured path to success. They combine technical knowledge with practical equipment maintenance training to help participants boost efficiency, prevent downtime, and build confidence in managing critical equipment systems.

Ready to grow your career and strengthen your technical skills? Enroll today in Haward Technology Middle East’s Maintenance, Reliability & Rotating Equipment Engineering courses and move closer to mastering the science of reliable industrial performance.