TRAINING COURSES

📚 Courses We Offer 📚

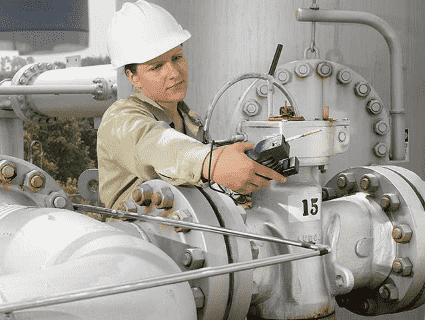

Facility Integrity, Inspection, Metallurgy & Corrosion Engineering

Explore our expertly curated courses designed to elevate your skills and knowledge.

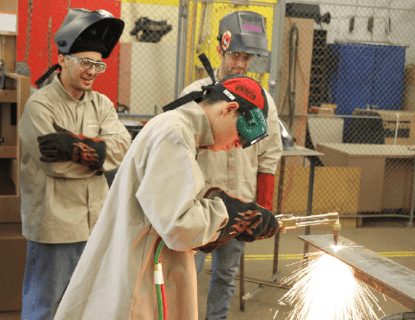

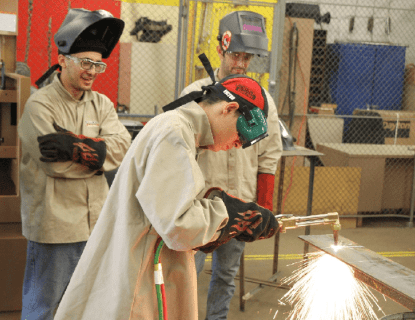

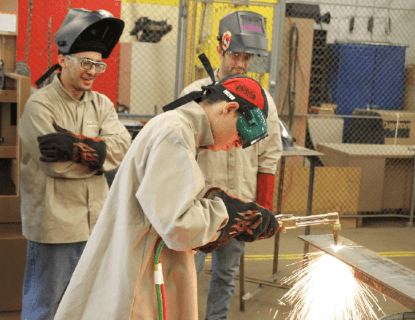

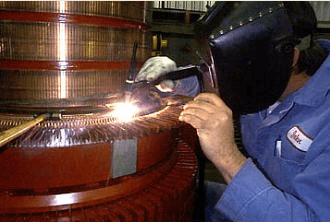

- FE0430 : Welding Engineering and Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date : Feb 24 - Feb 28 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

- FE0935 : API 571: Corrosion and Materials (API Exam Preparation Training)

- Date : Feb 02 - Feb 06 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- FE0430 : Welding Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date : Feb 24 - Feb 28 2025 / 5 Days

- Location : London, United Kingdom

- Course Details

- FE0985 : Thermal Infrared Testing ASNT Level-1 Training & Certification (ASNT, SNT-TC-1A)

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- FE0433 : Welding Defects Analysis

- Date : Jan 26 - Jan 30 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- FE0775 : Visual Testing ASNT Level I-II Training & Certification (ASNT, SNT-TC-1A)

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- FE0171 : Pipeline & Piping Inspection, Maintenance, Repair & Integrity Assessment

- Date : Jan 12 - Jan 16 2025 / 5 Days

- Location : Doha, Qatar

- Course Details

- FE0570 : API 579-1/ASME FFS-1: Fitness-for-Service (FFS) of Process Plant Equipment, Pressure Vessels, Piping & Storage Facilities

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- FE0430 : Welding Technology: ASME IX Welding, Fabrication, Brazing, Inspection & Fusing Qualification

- Date : Jul 06 - Jul 10 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- FE0935 : API 571: Damage Mechanisms Affecting Fixed Equipment in the Refining, Petrochemical & Petroleum Industries (API Exam Preparation Training)

- Date : Aug 03 - Aug 07 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- FE0070 : ASME B31.3 Process Piping Design, Construction, Maintenance & Mechanical Integrity

- Date : Oct 05 - Oct 09 2025 / 5 Days

- Location : Kuwait City, Kuwait

- Course Details

- FE0700 : API 570: Piping Inspector (API Exam Preparation Training)

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- FE0935 : API 571: Corrosion and Materials (API Exam Preparation Training)

- Date : Jan 19 - Jan 23 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0930 : API 577: Welding Inspection and Metallurgy (API Exam Preparation Training)

- Date : Jul 20 - Jul 24 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0570 : API 579-1/ASME FFS-1: Fitness-for-Service (FFS) of Process Plant Equipment, Pressure Vessels, Piping & Storage Facilities

- Date : Feb 09 - Feb 13 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0710 : API 653: Aboveground Storage Tank Inspector (API Exam Preparation Training)

- Date : Feb 16 - Feb 20 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0860 : AWS Certified Welding Inspector (CWI)

- Date : Apr 20 - Apr 24 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0068 : Corrosion Control in the Refining Industry

- Date : Apr 13 - Apr 17 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0104 : Material Selection & Failure Analysis

- Date : May 04 - May 08 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- FE0700 : API 570: Piping Inspector (API Exam Preparation Training)

- Date : Dec 07 - Dec 11 2025 / 5 Days

- Location : Dubai, UAE

- Course Details

- FE0935 : API 571: Corrosion and Materials (API Exam Preparation Training)

- Date : Nov 02 - Nov 06 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0930 : API 577: Welding Inspection and Metallurgy (API Exam Preparation Training)

- Date : Dec 14 - Dec 18 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0570 : API 579 Fitness For Service Course with certifcation exam

- Date : Sep 14 - Sep 18 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- FE0860 : AWS Certified Welding Inspector (CWI)

- Date : Nov 09 - Nov 13 2025 / 5 Days

- Location : Al Khobar, KSA

- Course Details