TRAINING COURSES

📚 Courses We Offer 📚

Subsurface Production Operations, Drilling, Reservoir & Petroleum Engineering

Explore our expertly curated courses designed to elevate your skills and knowledge.

- DE0920 : Electric Submersible Pumping

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- DE0500 : Screening of Oil Reservoirs for Enhanced Oil Recovery

- Date : Jan 18 - Jan 22 2026 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- DE0338 : Concept Selection and Specification of Production Facilities in Field Development Projects

- Date : Jan 25 - Jan 29 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- DE0960 : Well Composite, Construction Integrity & Completion

- Date : Feb 01 - Feb 05 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- DE0500 : Screening of Oil Reservoirs for Enhanced Oil Recovery

- Date : Feb 08 - Feb 12 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- DE1091 : Stimulation Engineer: Enhanced Recovery & Reservoir Treatment

- Date : Jan 26 - Jan 30 2026 / 5 Days

- Location : Rome, Italy

- Course Details

- DE0290 : Introduction to Petroleum Engineering

- Date : Feb 01 - Feb 05 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0290 : Introduction to Petroleum Engineering

- Date : Nov 08 - Nov 12 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0586 : Integrating Petrophysical, Geomechanics & Seismic Measurements

- Date : Jan 05 - Jan 09 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- DE0899 : Geophysical Data Analyst: Seismic Interpretation & Modeling

- Date : Jan 26 - Jan 30 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0899 : Geophysical Data Analyst: Seismic Interpretation & Modeling

- Date : Jan 26 - Jan 30 2026 / 5 Days

- Location : London, United Kingdom

- Course Details

- DE0625 : Generalist Engineer: Cross-Disciplinary Oil & Gas Operations Fundamentals

- Date : Jan 25 - Jan 29 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- DE0923 : Petroleum Project Economics & Risk Analysis

- Date : Feb 01 - Feb 05 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- DE0087 : Fractured Reservoir Characterisation

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0750 : Wireline Operations & Techniques

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0441(AD6) : Advanced PVT and EOS Fluid Characterization

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0611(KP4) : Basic Drilling

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0996 : Well Testing & Production Optimization Operations

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0805 : Coring and Core Analysis

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0972 : Well Integrity Management

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0624 : Understand Water Flooding, Reservoir Souring and Water Breakthrough

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0815 : Water Injection Technology: Water Flooding A-Z

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

- DE0960 : Well Composite, Construction Integrity & Completion

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- DE0250 : Subsurface Production Operations

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Doha, Qatar

- Course Details

Petroleum Engineering Programs

Build Deep Technical Expertise for High-Demand Energy Roles

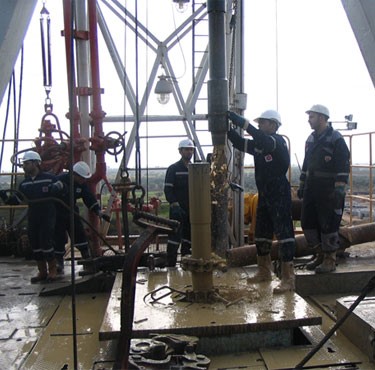

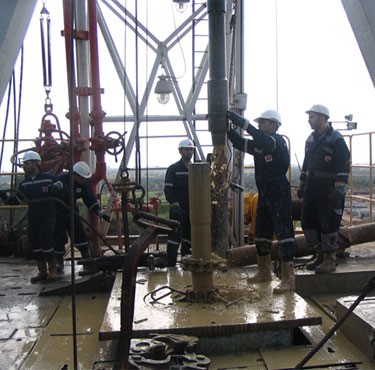

Haward Technology Middle East delivers advanced Petroleum Engineering training for professionals working in exploration, drilling, production, and refining. Designed for real-world energy challenges, our programs equip engineers with the specialized knowledge and skills needed to perform confidently in upstream and downstream environments.

Why Professionals Choose Us for Petroleum Engineering Training

As the world’s leading accredited technical training provider, Haward Technology Middle East offers hands-on, experience-based learning built to meet international industry standards. With a clear focus on bridging global skill gaps, we help engineers develop expertise that’s both practical and highly relevant.

With over 8,000 specialized courses and a network of more than 800 expert instructors, our training programs give participants access to proven techniques, current technologies, and industry best practices.

Convenient Petroleum Engineering Courses Online

For engineers seeking flexibility without sacrificing quality, Haward Technology Middle East offers Petroleum Engineering courses online that are fully aligned with industry needs. These self-paced programs are ideal for working professionals who want to upskill or reskill without disrupting their careers.

Each course blends theory with real-world applications, perfect for professionals involved in drilling, field operations, reservoir studies, and production engineering. Popular course topics include:

- Introduction to Petroleum Engineering

- Production and Reservoir Engineering

- Offshore Oil & Gas Facilities

- Enhanced Oil Recovery Methods

Courses are delivered by seasoned professionals who bring deep field experience, giving you insights that are both actionable and industry-tested.

Industry-Recognized Petroleum Engineering Certificate Online

For those looking to strengthen their qualifications, our Petroleum Engineering certificate online offers an effective pathway to career advancement. This certification confirms your technical skills and shows your commitment to staying current with the latest tools and practices in the energy sector.

Built for flexibility, these certificate programs are structured to accommodate your schedule while covering all core aspects of petroleum engineering.

Professionals earning this certification often move into roles such as:

- Reservoir and Production Engineers

- Oilfield Operations Supervisors

- Technical Consultants

- Project and Asset Managers

Holding a certified credential also helps meet compliance requirements and opens the door to international job opportunities.

Specialized Drilling Engineering Courses

Drilling operations require precision, planning, and technical mastery. Our drilling engineering courses are built to train engineers in the full lifecycle of well design, development, and operation, helping to improve performance, safety, and cost efficiency in the field. Topics covered include:

- Well Planning and Design

- Drilling Fluids and Hydraulics

- Casing and Cementing Techniques

- Well Control and Blowout Prevention

- Horizontal and Directional Drilling

These courses are valuable for professionals working in exploration, drilling operations, field development, and maintaining well integrity.

Online Drilling Engineering Courses for On-the-Go Professionals

If you're looking to enhance your drilling knowledge without pausing your work schedule, our drilling engineering courses online offer the perfect solution. Delivered through an interactive online platform, these programs provide the same technical depth as our in-person training but with the convenience of remote learning. Courses are ideal for:

- Junior engineers entering drilling roles

- Mid-career professionals looking to upgrade skills

- Managers and supervisors aiming to improve operational efficiency

Each course features interactive content, case studies, simulations, and instructor support to help participants gain confidence in handling on-site drilling challenges.

Practical Training with Real-World Relevance

Our petroleum-focused training programs are built around real field conditions. We understand the risks and responsibilities engineers face daily, and we tailor our training to help you solve problems, not just understand theories. Key focus areas include:

- Oilfield Equipment Maintenance

- Health, Safety & Environmental Practices

- Field Development Planning

- Reservoir Performance Monitoring

These courses are suitable for professionals working in:

- Onshore and Offshore Facilities

- Production Plants

- Exploration and Drilling Companies

- National and International Oil Firms

With access to simulation tools, detailed case studies, and collaborative workshops, our participants finish each program with the knowledge to apply their skills effectively on the job.

A Training Approach That Goes Beyond Lectures

At Haward Technology Middle East, learning is built around interaction and engagement. We use a mix of training tools and strategies to help engineers absorb, apply, and retain knowledge long after the course ends. Our teaching method includes:

- In-Depth Lectures

- Hands-On Exercises

- Case-Based Learning

- Software and Hardware Simulations

- Video Demonstrations and Scenario Reviews

We also include regular assessments and peer discussions to reinforce learning and improve decision-making skills under pressure.

Learn from Global Leaders in Petroleum Engineering

Our instructors are more than educators; they are seasoned experts, many of whom have worked in senior positions across global oil and gas companies. With decades of experience and technical achievements, they bring unmatched value to each training session. You’ll learn directly from those who’ve done the work and led the change.

Your Next Career Move Starts Here

Want to grow your career in petroleum engineering? Enroll in Petroleum Engineering courses online, get certified through our Petroleum Engineering certificate online, or deepen your skills with our drilling engineering courses and drilling engineering courses online.

Browse our course catalog or contact our team to find the right program for your goals. With Haward Technology Middle East, you gain more than knowledge; you gain the confidence to lead in one of the world’s most demanding industries.

.jpg)

.jpg)