Facility Integrity, Inspection, Metallurgy & Corrosion Engineering

In the complex and demanding landscape of industrial operations, expertise in Facility Integrity, Inspection, Metallurgy, and Corrosion Engineering is essential for ensuring safety, reliability, and efficiency. Our comprehensive courses are meticulously designed to equip learners with the knowledge and skills necessary to excel in these crucial areas. By enrolling in our programs, learners will embark on a transformative educational journey, gaining invaluable insights and practical experience that will enable them to become innovators and leaders in their respective fields.

Facility Integrity Engineering: Facility integrity engineering focuses on maintaining the safety and performance of industrial assets throughout their lifecycle. Our courses cover a wide array of topics, including risk-based inspection, integrity management systems, and failure analysis. Learners will delve into the principles of asset integrity, understanding how to develop and implement strategies to prevent failures and extend the life of facilities. With hands-on experience using industry-standard tools and software, learners will be prepared to manage complex integrity challenges and drive improvements in operational safety and efficiency.

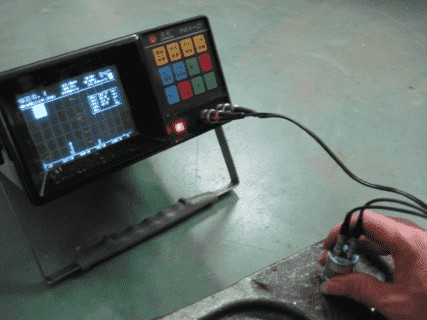

Inspection Engineering: Inspection engineering is critical for the early detection of defects and the prevention of catastrophic failures. Our curriculum encompasses key areas such as non-destructive testing (NDT) techniques, inspection planning, and quality assurance. Learners will explore the intricacies of various NDT methods, including ultrasonic testing, radiographic testing, and magnetic particle testing, gaining insights into how to accurately assess the condition of materials and components. Through practical lab work and industry-relevant projects, learners will develop the technical expertise and problem-solving skills necessary to ensure the integrity and reliability of industrial assets.

Metallurgy Engineering: Metallurgy engineering involves the study of the physical and chemical behavior of metallic elements and their mixtures, known as alloys. Our courses cover topics such as materials characterization, heat treatment, and failure mechanisms. Learners will gain a deep understanding of the properties and performance of different metals and alloys, learning how to select and process materials for specific applications. By studying the latest advancements in materials science, learners will be equipped to develop innovative solutions that enhance the durability and performance of industrial components.

Corrosion Engineering: Corrosion engineering focuses on understanding and preventing the degradation of materials due to chemical interactions with their environment. Our curriculum includes key areas such as corrosion mechanisms, corrosion control methods, and protective coatings. Learners will explore the principles of electrochemistry, materials selection, and corrosion monitoring, gaining insights into how to design and implement effective corrosion prevention strategies. Through practical projects and simulations, learners will develop the skills necessary to tackle complex corrosion challenges, contributing to the longevity and safety of industrial assets.

Benefits of Our Courses: Enrolling in our Facility Integrity, Inspection, Metallurgy, and Corrosion Engineering programs offers numerous advantages for learners, providing a robust foundation for professional growth and career advancement. Firstly, our courses are designed to offer a balanced blend of theoretical knowledge and practical experience. This ensures that learners can apply what they have learned in real-world scenarios, making them highly valuable to potential employers. Secondly, our programs foster critical thinking, creativity, and innovation. These skills are crucial for developing new strategies and solutions that address current and future challenges in these engineering disciplines.

Additionally, our courses provide learners with the opportunity to work with cutting-edge technologies and industry-standard software, ensuring they are proficient in the tools and techniques used by professionals. Our experienced faculty, who are experts in their respective fields, offer mentorship and insights, guiding learners through complex concepts and practical applications. The collaborative learning environment encourages teamwork and interdisciplinary collaboration, preparing learners to thrive in diverse, dynamic work settings.

Completing our programs can open doors to a wide range of career opportunities. Course completionists will be well-prepared to pursue roles in sectors such as oil and gas, petrochemicals, power generation, aerospace, and manufacturing, among others. Whether aiming to work in established industries or emerging sectors, the skills and knowledge gained from our courses will be invaluable. Our alumni have successfully transitioned into roles in leading companies, research institutions, and regulatory agencies, making significant contributions to technological advancements and operational excellence.

In conclusion, our comprehensive training in Facility Integrity, Inspection, Metallurgy, and Corrosion Engineering is designed to empower learners with the expertise and confidence needed to excel in today’s fast-paced, technology-driven world. By investing in their education through our courses, learners will not only enhance their professional skills but also contribute to the advancement of engineering practices, driving innovation and excellence in their chosen fields. Through our programs, learners will be equipped to tackle the complex challenges of modern industrial operations, pioneering solutions that promote safety, reliability, and sustainability.