COURSE OVERVIEW

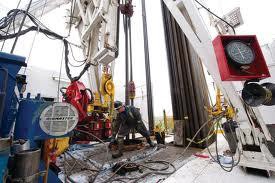

DE0448 : Drilling Problems and Drilling Optimization

OVERVIEW

| COURSE TITLE | : | DE0448 : Drilling Problems and Drilling Optimization |

| COURSE DATE | : | May 25 - May 29 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Konstantin Zorbalas |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 8500 |

Course Description

This practical and highly-interactive course includes real-life case studies and exercises where participants will be engaged in a series of interactive small groups and class workshops.

This course is designed to provide participants with a detailed and up-to-date overview of Drilling Problems and Drilling Optimization. It covers the drilling industry, key terminologies and the basic process of drilling wells; the drilling rig, pipe sticking, lost circulation and blowouts; the types of drilling muds, properties and their role in addressing drilling challenges; the importance of effective hole cleaning, hydraulics optimization and impact on drilling operations; the drill string components, stresses and failure modes; and the causes of high torque and drag and methods to mitigate them.

Further, the course will also discuss the geological causes of borehole instability and techniques for maintaining borehole integrity; identifying, preventing and remediating differential sticking; the surveying and bottom hole assembly (BHA) design; the fundamentals, tools and techniques for directional and horizontal drilling; the extended reach drilling (ERD), underbalanced and pressure drilling; and the drilling optimization software, technology, real-time data analysis and decision making.

During this interactive course, participants will learn the fundamentals of well control and the importance of maintaining wellbore pressure; the well control equipment and well control procedures, risk assessment and management and health, safety, and environmental (HSE) considerations; the cost management in drilling operations and the latest developments in high-performance fluids to address complex drilling challenges; the impact of robotics and automation on drilling efficiency and safety; and the sustainable practices in drilling operations.

link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesPractical Workshops & Work Presentations

Hands-on Practical Exercises & Case Studies

Simulators (Hardware & Software) & Videos

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

This course is no longer available.

Please check below for other scheduled dates.

OTHER SCHEDULED DATES

| Refrence | Date | Location | Instructor | Fee (USD) | Outline | Actions |

|---|---|---|---|---|---|---|

| DE0448 | Apr 05 - Apr 09 2026 (5 Days) | Cairo, Egypt | Mr. Konstantin Zorbalas | $ 8,000 | Outline | |

| DE0448 | Apr 12 - Apr 16 2026 (5 Days) | Doha, Qatar | Mr. Konstantin Zorbalas | $ 8,500 | Outline | |

| DE0448 | May 31 - Jun 04 2026 (5 Days) | Dubai, UAE | Mr. Konstantin Zorbalas | $ 8,000 | Outline | |

| DE0448 | Jul 05 - Jul 09 2026 (5 Days) | Istanbul, Turkey | Mr. Konstantin Zorbalas | $ 8,500 | Outline | |

| DE0448 | Aug 31 - Sep 04 2026 (5 Days) | London, United Kingdom | Mr. Konstantin Zorbalas | $ 8,800 | Outline | |

| DE0448 | Oct 04 - Oct 08 2026 (5 Days) | Doha, Qatar | Mr. Konstantin Zorbalas | $ 8,500 | Outline | |

| DE0448 | Nov 30 - Dec 04 2026 (5 Days) | Seville, Spain | Mr. Konstantin Zorbalas | $ 8,800 | Outline | |

| DE0448 | Jan 24 - Jan 28 2027 (5 Days) | Dubai, UAE | Mr. Konstantin Zorbalas | $ 8,000 | Outline | |

| DE0448 | Mar 14 - Mar 18 2027 (5 Days) | Cairo, Egypt | Mr. Konstantin Zorbalas | $ 8,000 | Outline |

RELATED COURSES

DE0805 : Coring and Core Analysis

- Date: Feb 22 - Mar 12 / 3 Days

- Location: Dubai, UAE

- Course Details Register

DE0979 : Pore Pressure & Well Control

- Date: Feb 22 - Mar 12 / 3 Days

- Location: Doha, Qatar

- Course Details Register

DE0338 : Concept Selection and Specification of Production Facilities in Field Development Projects

- Date: Feb 22 - Mar 12 / 3 Days

- Location: Dubai, UAE

- Course Details Register

DE0460 : Artificial Lift Systems & Optimization Technology

- Date: Feb 22 - Mar 12 / 3 Days

- Location: Doha, Qatar

- Course Details Register