COURSE OVERVIEW

ME0691 : Steam Generation and Distribution Operations Training

OVERVIEW

| COURSE TITLE | : | ME0691 : Steam Generation and Distribution Operations Training |

| COURSE DATE | : | Apr 14 - Apr 18 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Den Bazley |

| VENUE | : | Abu Dhabi, UAE |

| COURSE FEE | : | $ 5500 |

| Request For Course Outline | ||

Course Description

This practical and highly-interactive course includes real-life case studies and exercises where participants will be engaged in a series of interactive small groups and class workshops.

This course is designed to provide participants with a detailed and up-to-date overview of Steam Generation and Distribution Operations. It plays a critical role in enhancing production efficiency, facilitating thermal processes and supporting various industrial applications. Steam is primarily generated in high-pressure boilers using fuels such as natural gas, crude oil or refinery byproducts.

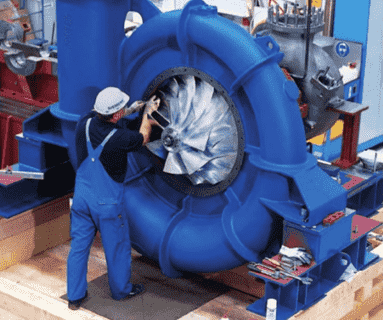

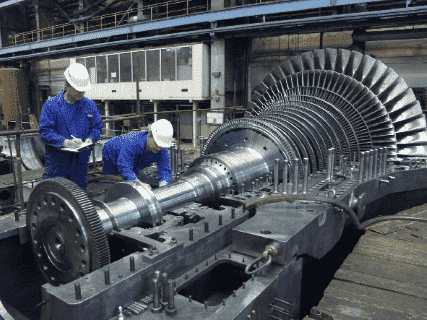

It is then distributed through an extensive pipeline network to drive steam turbines, assist in enhanced oil recovery (EOR) techniques like steam injection, power distillation columns and support heating and cleaning processes. Proper management of steam pressure, temperature, and condensate recovery is essential to optimize energy efficiency, minimize heat losses and ensure safe operations.

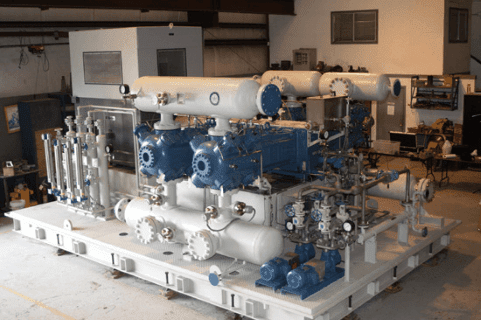

Effective water treatment, boiler maintenance and system insulation are key to preventing scaling, corrosion and operational downtime, making steam distribution a vital component of oil and gas processing facilities.

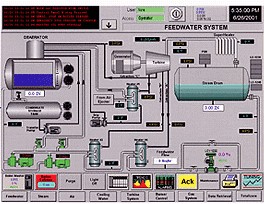

During this interactive course, participants will learn the steam boilers, fuel combustion and steam generation; the firing application and thermal efficiency; the boiler auxiliary equipment, feed water pump, valves, steam traps, fans, fire tube and water tube boilers; the combustion bases and fuel burners; the boiler instruments and its purpose; the typical P&I diagram for boilers and steam generators; the operation sequence and procedures; the steam demand and firing rate including pressure and pressure containing components; the basic control loops solving and the reason for problems and troubleshoot; and the boiler shutdown prevention and plant start up and shutdown.

link to course overview PDF

This course is designed to provide participants with a detailed and up-to-date overview of Steam Generation and Distribution Operations. It plays a critical role in enhancing production efficiency, facilitating thermal processes and supporting various industrial applications. Steam is primarily generated in high-pressure boilers using fuels such as natural gas, crude oil or refinery byproducts.

It is then distributed through an extensive pipeline network to drive steam turbines, assist in enhanced oil recovery (EOR) techniques like steam injection, power distillation columns and support heating and cleaning processes. Proper management of steam pressure, temperature, and condensate recovery is essential to optimize energy efficiency, minimize heat losses and ensure safe operations.

Effective water treatment, boiler maintenance and system insulation are key to preventing scaling, corrosion and operational downtime, making steam distribution a vital component of oil and gas processing facilities.

During this interactive course, participants will learn the steam boilers, fuel combustion and steam generation; the firing application and thermal efficiency; the boiler auxiliary equipment, feed water pump, valves, steam traps, fans, fire tube and water tube boilers; the combustion bases and fuel burners; the boiler instruments and its purpose; the typical P&I diagram for boilers and steam generators; the operation sequence and procedures; the steam demand and firing rate including pressure and pressure containing components; the basic control loops solving and the reason for problems and troubleshoot; and the boiler shutdown prevention and plant start up and shutdown.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesPractical Workshops & Work Presentations

Hands-on Practical Exercises & Case Studies

Simulators (Hardware & Software) & Videos

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

ME0447 : Rotating Equipment Selection, Operation, Maintenance, Inspection & Troubleshooting

- Date: Apr 20 - Apr 24 / 3 Days

- Location: Dubai, UAE

- Course Details Register

ME0754 : Basic Planning for Technician

- Date: Apr 20 - Apr 24 / 3 Days

- Location: Dubai, UAE

- Course Details Register

ME0015 : Centrifugal Compressor & Steam Turbine Design, Performance, Operation, Maintenance & Troubleshooting

- Date: Apr 20 - Apr 24 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

ME0670 : Centrifugal Gas Compressor: Operation, Control, Startup, Shutdown, Maintenance & Troubleshooting

- Date: Apr 20 - Apr 24 / 3 Days

- Location: Doha, Qatar

- Course Details Register