COURSE OVERVIEW

RE0200(EC2) : Maintenance Management, CMMS, KPI, Planning, Budgeting & Cost Reports

OVERVIEW

| COURSE TITLE | : | RE0200(EC2) : Maintenance Management, CMMS, KPI, Planning, Budgeting & Cost Reports |

| COURSE DATE | : | Feb 16 - Feb 20 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Steve Magalios |

| VENUE | : | Al Khobar, KSA |

| COURSE FEE | : | $ 5500 |

Course Description

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators.

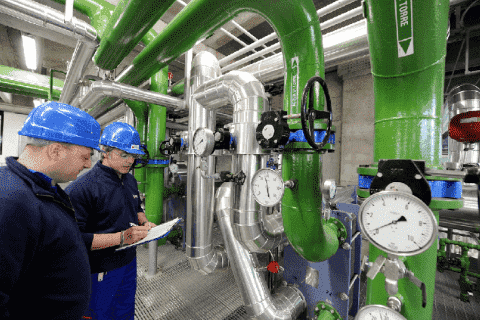

Maintenance planning, scheduling and work control are the most important elements in modern maintenance management. Maintenance planning and scheduling are also synonymous with control of maintenance. Further, maintenance planning and scheduling of work orders in addition to the control of such work are considered as the hub of a well functioning maintenance organization. In order for maintenance planning and scheduling to work many other systems need to work well. Most importantly equipment inspections through preventive maintenance, technical database such as bill of materials, work order history, and standard job plans. Maintenance spare part stores have to function well, see the above illustration picture.

In a world where sustainable cost-effectiveness and productivity is paramount, your focus is on increasing company revenue by enhancing the performance of your physical assets. Are you up to the challenge? Maintenance Management and plays a critical part within Physical Asset Management. By understanding the fundamental processes behind this strategy you will be able to identify the essential responsibilities you need to undertake in order to initiate a Maintenance Planning, Scheduling and Control program. But Maintenance Planning and Scheduling is not effective unless a strong reliability culture exists and reliability principles are understood and applied.

This course is designed to provide participants with a detailed and up-to-date overview of maintenance planning. It covers the maintenance classification and maintenance management process; the preventive predictive maintenance, predictive maintenance techniques, proactive and reactive maintenance; the PM & RFT policies, advanced maintenance policies, criticality analysis and reliability excellence; the CMMS benefits, work management, work request and work order tracking; the CM work order, PM work order, work order completion process and controlling maintenance work; the backlog monitoring, inventory control, asset management, work management and planning; and the overall equipment effectiveness (OEE), total effective equipment performance (TEEP) and benching.

During this interactive course, participants will learn to manage using KPI’s and identify the difference between hazard and risk as well as ALARP, safety plan and JSEA; recognize the difference between hazard and risk, ALARP, safety plan and JSEA; apply maintenance activities management; carryout time management, progress report, work completion and reporting; review maintenance budget and cost reports, calculate oil and fuel consumption, manage spare parts and classify materials; define the meaning of lead time, criticality of utilization and law of pareto; and identify the index of rotation (LIR & NIR), spare parts tests and stock handling costs as well as the stock ordering costs and economical order quantity (EOQ).

link to course overview PDFTRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesPractical Workshops & Work Presentations

Hands-on Practical Exercises & Case Studies

Simulators (Hardware & Software) & Videos

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

| Refrence | Date | Location | Instructor | Fee (USD) | Outline | Actions |

|---|---|---|---|---|---|---|

| RE0200(EC2) | Jan 11 - Jan 15 2026 (5 Days) | Dubai, UAE | Mr. Steve Magalios | $ 5,500 | Outline | |

| RE0200(EC2) | May 11 - May 14 2026 (4 Days) | Abu Dhabi, UAE | Mr. Steve Magalios | $ 4,500 | Outline | |

| RE0200(EC2) | Sep 06 - Sep 10 2026 (5 Days) | Al Khobar, KSA | Mr. Steve Magalios | $ 5,500 | Outline | |

| RE0200(EC2) | Nov 08 - Nov 12 2026 (5 Days) | Doha, Qatar | Mr. Steve Magalios | $ 6,000 | Outline |

RELATED COURSES

RE0626 : Certified Machine Lubricant Analyst (MLA) Level - II – ISO 18436-4/ICML Certification

- Date: Mar 29 - Apr 02 / 3 Days

- Location: Dubai, UAE

- Course Details Register

RE0010 : Professional Maintenance Auditor

- Date: Mar 29 - Apr 02 / 3 Days

- Location: Dubai, UAE

- Course Details Register

RE0058 : Certified Machinery Lubrication Engineer (MLE) ICML-MLE Certification

- Date: Feb 22 - Feb 26 / 3 Days

- Location: Dubai, UAE

- Course Details Register

RE0805-9D : Vibration Analyst Category: Category IV (Mobius Institute)

- Date: Mar 12 - Apr 16 / 3 Days

- Location: Dubai, UAE

- Course Details Register