TRAINING COURSES

📚 Courses We Offer 📚

Mechanical Engineering

Explore our expertly curated courses designed to elevate your skills and knowledge.

- ME0615 : Pumps & Compressors: Operation, Maintenance & Troubleshooting

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0089 : Steam Boilers Operation, Maintenance and Control System

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0562 : Pump Selection, Installation, Performance & Control

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0020 : Certified Boiler Operation, Control, Maintenance & Troubleshooting

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0122 : Valves, Safety Relief Valves, Strainers & Steam Traps

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Al Khobar, KSA

- Course Details

- ME0398 : Pumps, Compressors, Turbines & Troubleshooting

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Istanbul, Turkey

- Course Details

- ME0630 : The Layout of Piping Systems & Process Equipment

- Date : Jan 12 - Jan 16 2026 / 5 Days

- Location : London, United Kingdom

- Course Details

- ME0075 : Control Valves & Actuators

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0447 : Rotating Equipment: Pumps, Turbines & Compressors Technology: Design, Selection, Operation, Control, Inspection, Maintenance & Troubleshooting

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0138 : Application of Standards in Boiler, Pressure Vessel & Piping Systems

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0027 : Centrifugal Pump Selection, Construction, Operation, Maintenance, Repair & Troubleshooting

- Date : Jan 11 - Jan 15 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0240 : Advanced Valve Technology: Design, Selection, Installation, Applications, Sizing, Inspection, Maintenance & Troubleshooting

- Date : Jan 18 - Jan 22 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0616 : Compressor Operation, Maintenance & Troubleshooting

- Date : Jan 18 - Jan 22 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0015 : Centrifugal Compressor & Steam Turbine Design, Performance, Operation, Maintenance & Troubleshooting

- Date : Jan 18 - Jan 22 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0630 : The Layout of Piping Systems & Process Equipment

- Date : Jan 25 - Jan 29 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0098 : Pump Technology

- Date : Jan 25 - Jan 29 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0045J1 : Design, Fabrication & Testing of ASME VIII Pressure Vessels

- Date : Jan 25 - Jan 29 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0397 : Practical Pump & Valve Technology: Selection, Operation, Control, Maintenance & Troubleshooting

- Date : Feb 01 - Feb 05 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

- ME0562 : Pump Selection, Installation, Performance & Control

- Date : Feb 01 - Feb 05 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0089 : Steam Boilers Operation, Maintenance and Control System

- Date : Feb 02 - Feb 06 2026 / 5 Days

- Location : London, United Kingdom

- Course Details

- ME0398 : Pumps, Compressors, Turbines & Troubleshooting

- Date : Feb 08 - Feb 12 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0615 : Pumps & Compressors: Operation, Maintenance & Troubleshooting

- Date : Feb 08 - Feb 12 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0138 : Application of Standards in Boiler, Pressure Vessel & Piping Systems

- Date : Feb 08 - Feb 12 2026 / 5 Days

- Location : Cairo, Egypt

- Course Details

- ME0160 : Introduction to HVAC Design for Oil and Gas Industry

- Date : Jan 04 - Jan 08 2026 / 5 Days

- Location : Dubai, UAE

- Course Details

Mechanical Engineers

Mechanical Engineering Training Courses

Mechanical engineering drives the heartbeat of every industrial operation. Haward Technology Middle East offers comprehensive training programs tailored for engineers, technicians, and maintenance professionals seeking to refine their skills, tackle real-world challenges, and lead with confidence.

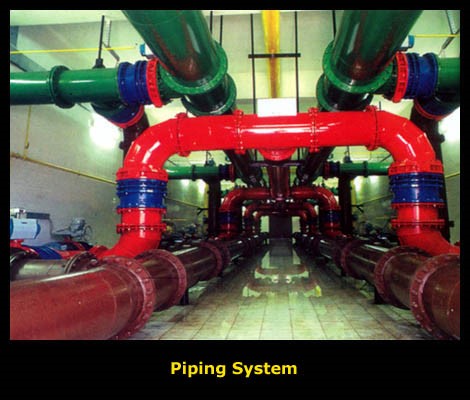

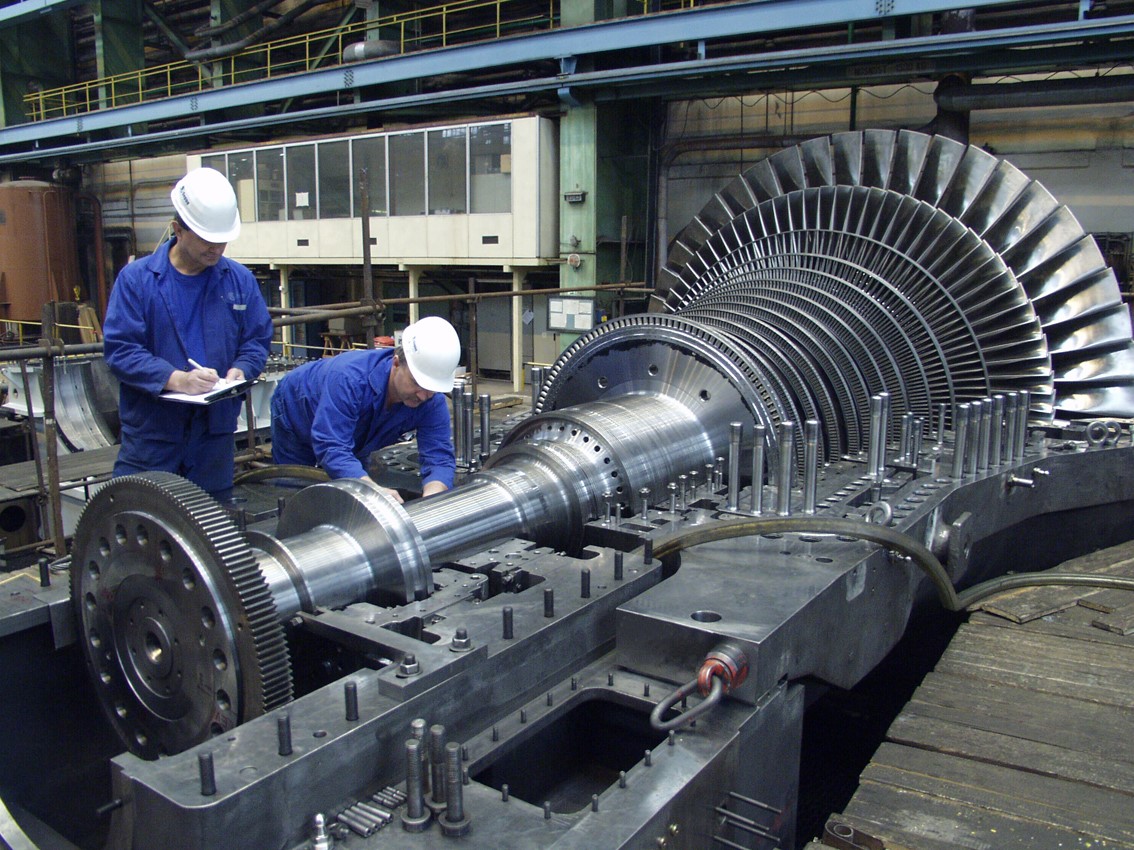

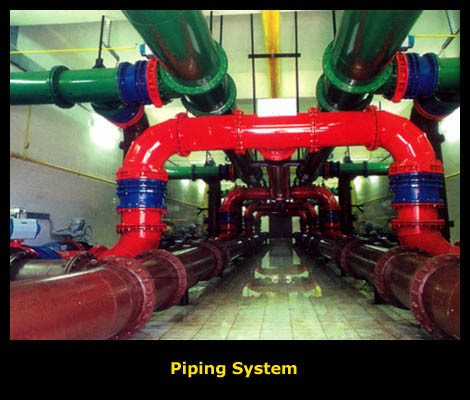

Our mechanical engineering training courses cover critical areas, including rotating machinery, piping systems, HVAC, corrosion control, and failure analysis. Each course is designed to reflect practical field requirements, regional industry demands, and international best practices.

In the Middle East, where major industrial sectors operate in challenging environments, expertise in mechanical engineering is essential. We help professionals develop the hands-on skills and technical knowledge needed to keep operations safe, efficient, and sustainable.

Why Mechanical Engineering Training Matters in This Region

Industries across the Gulf and surrounding regions are expanding rapidly. With growing demand in oil and gas, manufacturing, utilities, and infrastructure, there's a constant need for professionals trained in modern mechanical systems. Equipment reliability, energy efficiency, and safety compliance cannot be left to chance.

Our mechanical engineering courses address these needs with focused, technical content that builds both core and advanced competencies. Participants learn how to design, operate, and maintain systems that meet local regulations and global standards.

Comprehensive Course Topics for Practical Mastery

Haward Technology Middle East believes in structured learning that prepares professionals for real-world challenges. Instructors lead our mechanical engineering training courses with years of field experience and cover:

- Pump, compressor, and turbine operation

- HVAC system design and efficiency improvement

- Piping layouts, stress analysis, and code compliance

- Lubrication and seal management

- Condition monitoring and vibration diagnostics

- Corrosion prevention and mechanical integrity

- Failure analysis and reliability strategies

Each course combines theory with real-life case studies, interactive workshops, and practical sessions to ensure immediate application in the workplace.

Who Should Attend These Courses?

Our mechanical engineering training is ideal for:

- Mechanical engineers in design, maintenance, and inspection roles

- Plant operators and supervisors in the oil and gas, petrochemical, or power sectors

- Maintenance technicians seeking technical advancement

- Facility engineers handling HVAC, piping, or pressure systems

- Reliability engineers and asset integrity specialists

- Quality control and HSE professionals in mechanical settings

Experienced professionals benefit by updating their knowledge, while newcomers build a solid foundation that aligns with regional industry needs.

Our Delivery Method: Practical, Professional, Proven

At Haward Technology Middle East, we deliver training that reflects real industry needs. Our sessions combine instructor-led discussions with simulations, group activities, and hands-on demonstrations to provide a comprehensive learning experience. Each course is structured to encourage interaction, skill development, and confidence in applying knowledge in real-world environments.

Participants benefit from:

- Up-to-date content aligned with international standards

- Trainers with extensive field and project experience

- Interactive course materials and technical workbooks

- Immediate feedback and practical assessments

- Training certificates recognized across industries in the Middle East and beyond

We understand the regional operating environment. Our courses address the challenges unique to high-temperature zones, desert climates, complex processing facilities, and remote locations.

Industry-Relevant Training for Maintenance Professionals

Maintenance plays a critical role in minimizing downtime, extending asset life, and ensuring operational safety. Our maintenance engineer training courses provide in-depth coverage of reliability methods, maintenance planning, root cause analysis, and asset performance management.

Participants gain hands-on knowledge that can be applied directly to real-world maintenance strategies, reducing reactive breakdowns and improving overall plant performance. These maintenance engineer training courses are ideal for those working in fast-paced environments where predictive and preventive approaches are essential to success.

Why Choose Us?

Haward Technology Middle East has built a reputation as a leading provider of technical training across the Gulf and surrounding regions. With thousands of professionals trained over the years, our legacy rests on quality, depth, and regional relevance.

We go beyond surface-level training. Our mechanical engineering courses are developed in collaboration with major industrial employers and delivered by subject-matter experts who understand what it takes to succeed in the field.

We combine local insight with international standards. This balance allows us to support industries in achieving their targets while equipping professionals with globally applicable skills. We also regularly update our courses to keep pace with new technologies, updated codes, and changing industry expectations.

Start Your Training Journey with Us

If you are ready to improve your mechanical engineering knowledge, reduce operational risks, and contribute more confidently to your organization, then our training is the place to begin.

Our mechanical engineering programs are the key to unlocking improved system performance, more effective maintenance strategies, and extended equipment life. Join professionals across the region who trust us to support their technical growth.

Explore our upcoming certification courses for mechanical engineers. With a comprehensive curriculum and expert knowledge, Haward Technology Middle East supports your professional journey every step of the way. Join thousands of professionals across the Middle East who trust our certified training and register now!