COURSE OVERVIEW

ME0616 : Compressor Operation, Maintenance & Troubleshooting

OVERVIEW

| COURSE TITLE | : | ME0616 : Compressor Operation, Maintenance & Troubleshooting |

| COURSE DATE | : | Feb 02 - Feb 06 2025 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Andrew Ladwig |

| VENUE | : | London, United Kingdom |

| COURSE FEE | : | $ 8800 |

| Request For Course Outline | ||

Course Description

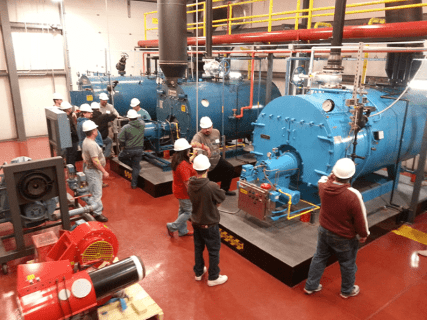

This course is designed to provide participants with a good working knowledge on the operation, maintenance and troubleshooting of compressors. It covers the common types, ranges of application, limitation and functions of compressors; the principles of equipment failure patterns; the common factors of why equipment fails; the different aspects of machinery corrosion; and the correct selection of materials for a given application.

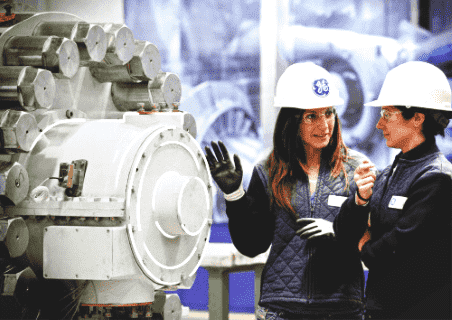

At the completion of the course, participants will be able to apply basic approaches to machinery troubleshooting; troubleshoot most possible faults and failures of pumps and compressor; carryout various approaches to be considered in applying corrective action; and employ the principles of dry gas, packing and mechanical seals.

The course will also cover the components and functions of compressors; the features of dry gas seal for centrifugal gas compressor; the troubleshooting of mechanical seal failure; the various maintenance and repair methods used; and the basic concept of bearing care, maintenance, bearing classification and lubrication management.

link to course overview PDF

At the completion of the course, participants will be able to apply basic approaches to machinery troubleshooting; troubleshoot most possible faults and failures of pumps and compressor; carryout various approaches to be considered in applying corrective action; and employ the principles of dry gas, packing and mechanical seals.

The course will also cover the components and functions of compressors; the features of dry gas seal for centrifugal gas compressor; the troubleshooting of mechanical seal failure; the various maintenance and repair methods used; and the basic concept of bearing care, maintenance, bearing classification and lubrication management.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

ME0021 : Certified Boiler Operation, Maintenance, Failure Analysis, Performance, Optimization & Steam System Management

- Date: Apr 06 - Apr 10 / 3 Days

- Location: Istanbul, Turkey

- Course Details Register

ME0584 : Certified Inspectors for Vehicle and Equipment

- Date: Apr 06 - Apr 10 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

ME0615 : Pumps & Compressors: Operation, Maintenance & Troubleshooting

- Date: Apr 06 - Apr 10 / 3 Days

- Location: Doha, Qatar

- Course Details Register

ME0077 : Control Valves, Actuators and Positioners

- Date: Apr 06 - Apr 10 / 3 Days

- Location: Doha, Qatar

- Course Details Register