COURSE OVERVIEW

ME0960 : Combustion Techniques

OVERVIEW

| COURSE TITLE | : | ME0960 : Combustion Techniques |

| COURSE DATE | : | Nov 24 - Nov 28 2024 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Den Bazley |

| VENUE | : | Abu Dhabi, UAE |

| COURSE FEE | : | $ 5500 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Mar 04 - Mar 07 2024 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Jun 24 - Jun 27 2024 (4 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Sep 23 - Sep 26 2024 (4 Days) | Location | : | Doha, Qatar | Classroom Fee (US$) | : | $ 5000 | Course Info |

| Date | : | Feb 02 - Feb 06 2025 (5 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Jun 23 - Jun 27 2025 (5 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Sep 14 - Sep 18 2025 (5 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 6000 | Course Info |

| Date | : | Dec 07 - Dec 11 2025 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

Course Description

Power generation and most processes are dependent on combustion of fuels. The effectiveness of the combustion process has a major influence on plant efficiency, reliability, safety and emissions. This course will improve your understanding of combustion and heat transfer and assist you to obtain the best out of your plant.

This course focuses on recent developments in burner design for process heating applications including boilers, furnaces, refinery operations, power plant and process plant. Particular emphasis is given to combustion aerodynamics and its influence on burner design, low NOx burner design and emission reduction techniques including reburn, SNCR, SCR and NOx storage techniques. These aspects are examined in relation to large natural gas burners, refinery burners, heavy fuel oil burners, flameless combustion, waste and bio-fuel firing, oxy-fuel firing and fluidized bed combustion. Large scale testing and the role of CFD in burner design are also covered.

This course is particularly concerned with improving the energy and environmental performance and design of gas and oil-fired, high-temperature furnaces and boilers. The main aim of the course is to provide greater understanding of the principles and practices associated with efficient design and operation of this type of plant. Lectures will be presented initially on the appropriate fundamental and practical aspects of combustion and heat transfer which are necessary to provide an understanding of the thermal behaviour of fuel-fired furnaces and boilers. Recent concerns on the harmful effects of global climate change have highlighted the need for energy conservation so that efficient burner operation is a major feature of the course. It is also necessary to minimise pollutant emissions (particularly NOx) from combustion processes so that this topic is covered in the presentations. Furnace design and control is still often based on tradition and experience despite the recent development of theoretical and experimental techniques which can assist in the prediction of furnace performance. Consequently, furnace modelling is a further major theme of the course.

Further, the course will provide a comprehensive insight into understanding the safety functions involved with ensuring a safe combustion process in boilers, furnaces, heaters and other fired process units. The concepts of Safety-Instrumented Burner Management Systems (SI-BMS) will be presented as the methodology to design a BMS to be compliant with latest codes and standards including NFPA 85, NFPA 86, FM 7605, ANSI/ISA 84, and IEC 61508, API 556, API 14C & BLRBAC.

This course focuses on recent developments in burner design for process heating applications including boilers, furnaces, refinery operations, power plant and process plant. Particular emphasis is given to combustion aerodynamics and its influence on burner design, low NOx burner design and emission reduction techniques including reburn, SNCR, SCR and NOx storage techniques. These aspects are examined in relation to large natural gas burners, refinery burners, heavy fuel oil burners, flameless combustion, waste and bio-fuel firing, oxy-fuel firing and fluidized bed combustion. Large scale testing and the role of CFD in burner design are also covered.

This course is particularly concerned with improving the energy and environmental performance and design of gas and oil-fired, high-temperature furnaces and boilers. The main aim of the course is to provide greater understanding of the principles and practices associated with efficient design and operation of this type of plant. Lectures will be presented initially on the appropriate fundamental and practical aspects of combustion and heat transfer which are necessary to provide an understanding of the thermal behaviour of fuel-fired furnaces and boilers. Recent concerns on the harmful effects of global climate change have highlighted the need for energy conservation so that efficient burner operation is a major feature of the course. It is also necessary to minimise pollutant emissions (particularly NOx) from combustion processes so that this topic is covered in the presentations. Furnace design and control is still often based on tradition and experience despite the recent development of theoretical and experimental techniques which can assist in the prediction of furnace performance. Consequently, furnace modelling is a further major theme of the course.

Further, the course will provide a comprehensive insight into understanding the safety functions involved with ensuring a safe combustion process in boilers, furnaces, heaters and other fired process units. The concepts of Safety-Instrumented Burner Management Systems (SI-BMS) will be presented as the methodology to design a BMS to be compliant with latest codes and standards including NFPA 85, NFPA 86, FM 7605, ANSI/ISA 84, and IEC 61508, API 556, API 14C & BLRBAC.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

ME0027 : Centrifugal Pump Selection, Construction, Operation, Maintenance, Repair & Troubleshooting

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register

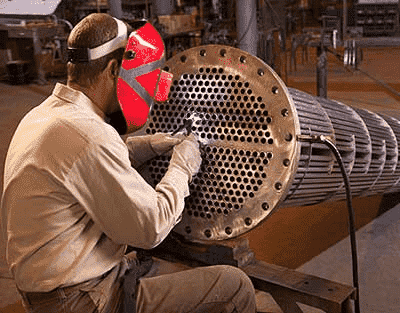

ME0062 : Heat Exchanger Operation, Maintenance & Repair

- Date: Jan 06 - Jan 10 / 3 Days

- Location: London, United Kingdom

- Course Details Register

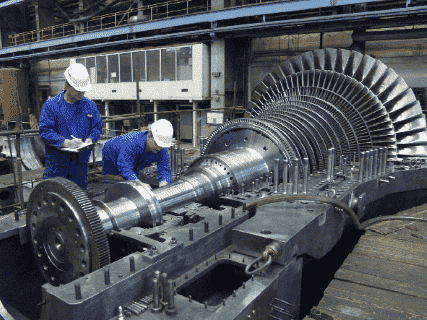

ME0015 : Centrifugal Compressor & Steam Turbine Design, Performance, Operation, Maintenance & Troubleshooting

- Date: Jan 05 - Jan 09 / 3 Days

- Location: Doha, Qatar

- Course Details Register

ME0615 : Operation, Maintenance & Troubleshooting of Pumps & Compressors

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register