COURSE OVERVIEW

FE0029-4D : API 576: Inspection of Pressure Relieving Devices

OVERVIEW

| COURSE TITLE | : | FE0029-4D : API 576: Inspection of Pressure Relieving Devices |

| COURSE DATE | : | Jan 15 - Jan 18 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. George Poulos |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 5500 |

| Request For Course | ||

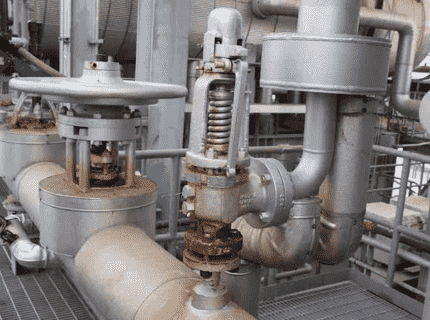

Course Description

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. This course is designed to provide delegates with a detailed and up-to-date overview of pressure-relieving devices inspection in accordance with API 576. It covers the recommended practice that describes the inspection and repair practices for automatic pressure-relieving devices commonly used in the oil and petrochemical industries. As a guide to the inspection and repair of these devices in the user?s plant, it is intended to ensure their proper performance. Further, this course will also discuss the dimensional characteristics of pressure-relief valves; the operational characteristics of system and device pressures; the pressurerelief devices; and the causes of improper performance of pressure relieving devices in corrosion, damaged seating surfaces, failed spring, improper setting and adjustment.During this interactive course, participants will be able to describe the plugging and sticking, misapplication of materials, improper location, history or identification and rough handling; the improper differential between operating and set pressures, improper discharge piping test procedures and improper handling, installation and selection of rupture disks; the inspection and testing of pressure relieving devices; the shop inspection and overhauling, visual on-stream inspection, inspection frequency and time of inspection; and the records and reports, its objectives, responsibilities, sample records and report systems.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

FE0771 : Ultrasonic Testing Level-II Training & Certification (ASNT, SNT-TC-1A)

- Date: Feb 09 - Feb 13 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

FE0630 : Material Certification Management

- Date: Feb 09 - Feb 13 / 3 Days

- Location: Dubai, UAE

- Course Details Register

FE0570 : API 579? Fitness For Service Course with certifcation exam

- Date: Feb 09 - Feb 13 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

FE0775 : Visual Testing ASNT Level I-II Training & Certification (ASNT, SNT-TC-1A)

- Date: Feb 09 - Feb 13 / 3 Days

- Location: Istanbul, Turkey

- Course Details Register