COURSE OVERVIEW

RE0020 : Effective Reliability Maintenance & Superior Maintenance Strategies

OVERVIEW

| COURSE TITLE | : | RE0020 : Effective Reliability Maintenance & Superior Maintenance Strategies |

| COURSE DATE | : | Mar 03 - Mar 07 2024 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Karl Thanasis |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 6000 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Feb 09 - Feb 13 2025 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | May 19 - May 23 2025 (5 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Aug 10 - Aug 14 2025 (5 Days) | Location | : | Doha, Qatar | Classroom Fee (US$) | : | $ 6000 | Course Info |

| Date | : | Nov 16 - Nov 20 2025 (5 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 5500 | Course Info |

Course Description

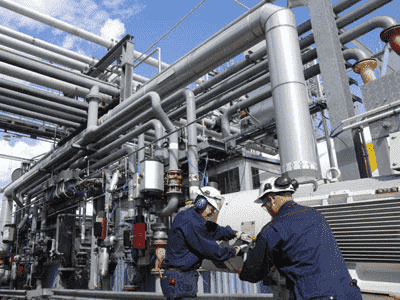

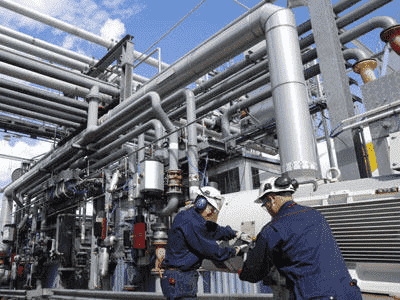

This practical and highly-interactive course includes real-life case studies and exercises where participants will be engaged in a series of interactive small groups and class workshops. The chronic problem that many companies struggle with regarding reliability maintenance is transforming their mindset from being reactive to being predictive. The differences are extreme. Reactive maintenance doesnt address machine problems until production is impaired or machines fail. A next phase is preventive. This mindset involves repairing bearings, belts and machines based on a schedule or machine hours. What this doesnt insure is machine failure causing unplanned downtime and unexpected costs. The predictive mindset is proactive. It involves collecting and analyzing machinery information on a periodic basis including vibration, ultrasonic and temperature readings. Predictive maintenance addresses and corrects the root causes of machine problems. It promotes reliability. The benefits of predictive maintenance are that it allows a company to plan down-time and repair machinery on a scheduled basis. Also, it identifies which machines and parts need to be repaired and replaced and which do not.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Virtual Course

- Course Details Register

RE0804 : ISO Vibration Certification Level III (CAT III-ISO 18436) Training, Exam & Certification (Mobius Institute)

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

RE0946 : Material Handling, Control and Spare Parts Movements

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register

RE0017 : Certified Maintenance & Reliability Professional (CMRP) (SMRP Exam Preparation Training)

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Kuwait City, Kuwait

- Course Details Register