COURSE OVERVIEW

ME0313 : Steam Turbine Operation & Maintenance

OVERVIEW

| COURSE TITLE | : | ME0313 : Steam Turbine Operation & Maintenance |

| COURSE DATE | : | Oct 07 - Oct 10 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Ahmed Mady |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 5000 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Feb 23 - Feb 27 2025 (5 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Sep 07 - Sep 11 2025 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

Course Description

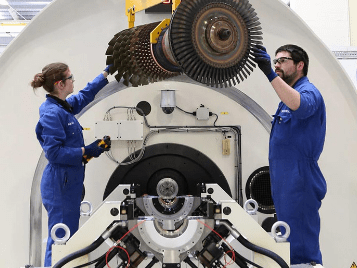

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. This course is designed to provide delegates with a detailed and up-to-date knowledge of steam turbine operation. It covers the main components in systems including lubricating oil systems, steam and water seal systems and hydraulic power units; the irregular operations within a system; the locations of the turbine supervisory instrument and their functions; the steam turbine control concepts; and the cause and effects of the thermal stress on normal turbine operations. This course will further discuss a comprehensive coverage of the steam turbine including the various components of steam system. It has been completely revised, reorganized and updated to include the latest techniques in steam turbine design, operation, maintenance, performance, optimization, inspection, control, troubleshooting, safety and steam system management. The course utilizes actual case studies from around the world to highlight the topics discussed.At the completion of this course, participants will be able to perform disassembling and assembling major turbine components safely; improve inspection/repair techniques; identify the different types of distress and irregular operating conditions caused by vibration of different components and potential results; as well as employ loss prevention method.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

ME0027 : Centrifugal Pump Selection, Construction, Operation, Maintenance, Repair & Troubleshooting

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register

ME0045 : ASME VIII Pressure Vessel Design, Fabrication & Testing

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register

ME0172 : INDUSTRIAL EQUIPMENT & TURBOMACHINERY: Pumps, Compressors, Turbines & Motors: Selection, Sizing, Applications, Operation, Diagnostic Testing, Troubleshooting, Maintenance & Failure Analysis

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Cairo, Egypt

- Course Details Register

ME0615 : Operation, Maintenance & Troubleshooting of Pumps & Compressors

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register