COURSE OVERVIEW

FE0320 : Metallurgy, Corrosion and Prevention of Failures: Material Selection and Properties

OVERVIEW

| COURSE TITLE | : | FE0320 : Metallurgy, Corrosion and Prevention of Failures: Material Selection and Properties |

| COURSE DATE | : | Aug 12 - Aug 15 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. George Poulos |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 5000 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Feb 23 - Feb 27 2025 (5 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Nov 02 - Nov 06 2025 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

Course Description

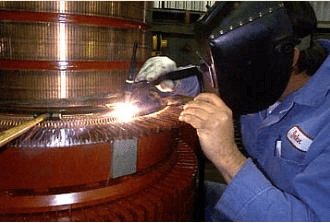

This practical and highly-interactive course includes various practical sessions and. Theory learned will be applied using our state-of-the-art simulators. Metallurgy: this section of the course discusses metals and the metallurgical characteristics of various metals. It provides an explanation of physical characteristics of metals, including the reason metals behave differently than non-metals. This section of the course also explains how and why different metals are selected for specific environmental purposes, including resistance to wear, corrosion, heat, cold, repeated stress, and impact. This is a lecture and problem-solving section that also deals with the metallurgical aspects of welding. Emphasis will be placed on mechanical metallurgy, materials selection, and the fundamentals of welding technology, welding metallurgy, inspection and quality of welds. Corrosion: this section of the course focuses on the fundamentals of corrosion as well as the potential problems caused by corrosion. It provides a review of the causes of corrosion and the methods for identification, monitoring and control. An understanding of corrosion and its control is vital for any company hoping to avoid the high costs that can be directly or indirectly attributed to corrosion. This section of the course also presents fundamental principles of corrosion and assists participants in recognizing corrosion problems, determining their causes, and understanding and selecting control methods. Emphasis is on the practical applications of corrosion technology to solve industrial corrosion problems.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

FE0710 : API 653: Aboveground Storage Tank Inspector (API Exam Preparation Training)

- Date: Jan 06 - Jan 10 / 3 Days

- Location: Abu Dhabi, UAE

- Course Details Register

FE0171 : Pipeline & Piping Inspection, Maintenance, Repair & Integrity Assessment

- Date: Jan 12 - Jan 16 / 3 Days

- Location: Doha, Qatar

- Course Details Register

FE0028 : API 598: Valve Inspection & Testing

- Date: Jan 06 - Jan 10 / 3 Days

- Location: Abu Dhabi, UAE

- Course Details Register

FE0860 : AWS Certified Welding Inspector (CWI)

- Date: Jan 12 - Jan 16 / 3 Days

- Location: Dubai, UAE

- Course Details Register