COURSE OVERVIEW

RE0242 : Machine Laser Alignment

OVERVIEW

| COURSE TITLE | : | RE0242 : Machine Laser Alignment |

| COURSE DATE | : | Jun 03 - Jun 06 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Dimitry Rovas |

| VENUE | : | Al Khobar, KSA |

| COURSE FEE | : | $ 4500 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Mar 04 - Mar 07 2024 (4 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 5000 | Course Info |

| Date | : | Sep 02 - Sep 05 2024 (4 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Dec 09 - Dec 12 2024 (4 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | May 25 - May 29 2025 (5 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Sep 14 - Sep 18 2025 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

Course Description

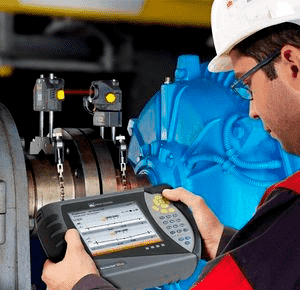

This practical and highly-interactive course includes practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. This course is designed to provide participants with a detailed and up-to-date overview of laser alignment. It covers the laser alignment techniques and maximum utilization of existing FixturLaser functions; the importance of proper shaft alignment and the symptoms of misalignment; the foundations, baseplate, piping effects and various types of couplings, flexible and rigid couplings; the alignment and coupling tolerances and the preliminary alignment checks; the different lasers and detectors systems and the advantages of laser alignment; and laser alignment procedures, mathematical relationships and ?on board? laser alignment calculations. At the end of the course, participants will be able to carryout adjustments for thermal growth; identify ?hot? alignment versus ?cold? alignment and moving machinery in the field; evaluate alignment considerations for specific equipment including electric motors, pumps, gear boxes, compressors, cooling towers, blowers & fans & internal combustion engines; and prevent misalignment severity and vibrations caused by misalignment.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

RE0190 : Practical Machinery Vibration Monitoring, Analysis & Predictive Maintenance: Vibration Techniques

- Date: Jan 05 - Jan 09 / 3 Days

- Location: Dubai, UAE

- Course Details Register

RE0225 : Certified Maintenance Planner (CMP)

- Date: Jan 05 - Jan 09 / 3 Days

- Location: Dubai, UAE

- Course Details Register

RE0096 : Advanced Inspection & Performance Evaluation of Rotating Equipment including Turbine Maintenance

- Date: Jan 05 - Jan 09 / 3 Days

- Location: Dubai, UAE

- Course Details Register

RE0190 : Practical Machinery Vibration Monitoring, Analysis & Predictive Maintenance: Vibration Techniques

- Date: Jan 05 - Jan 09 / 3 Days

- Location: Dubai, UAE

- Course Details Register