COURSE OVERVIEW

ME0731 : ASME Section II: Boiler & Pressure Vessel Materials

OVERVIEW

| COURSE TITLE | : | ME0731 : ASME Section II: Boiler & Pressure Vessel Materials |

| COURSE DATE | : | Jan 15 - Jan 18 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Dimitry Rovas |

| VENUE | : | Istanbul, Turkey |

| COURSE FEE | : | $ 5000 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Apr 22 - Apr 25 2024 (4 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Jul 08 - Jul 11 2024 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Jan 19 - Jan 23 2025 (5 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Apr 21 - Apr 25 2025 (5 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Jul 06 - Jul 10 2025 (5 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 6000 | Course Info |

| Date | : | Oct 05 - Oct 09 2025 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

Course Description

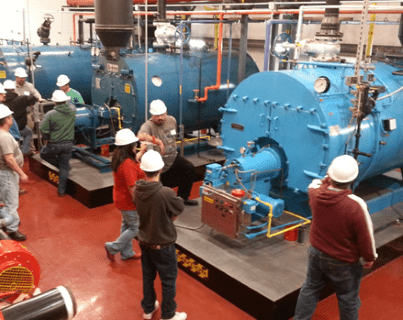

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. This course is designed to provide participants with a detailed and up-to-date overview of boiler and pressure vessel materials in accordance with ASME section II. It covers the ferrous and non-ferrous material specifications; the rolled structural steels, carbon, alloy, ferritic malleable iron castings, electric resistance-welded steel pipe, alloy steel and stainless steel; the nickel, molybdenum, carbonmolybdenum alloy steel, martensitic stainless, manganesevanadium-nickel, chromium-vanadium alloy steel, welded austenitic steel and gray iron castings; and the manganese-molybdenum-nickel, ferritic ductile iron pressure-retaining castings, forged or rolled 8 and 9% nickel alloy steel, high-temperature service and annealed or cold-worked austhenitic stainless steel.Further, the course will also discuss the age-hardening stainless-steel forgings including the test methods, practices and terminology for chemical analysis of steel products; the carbon steel and low-alloy steel pressure-vessel-component forgings with mandatory toughness requirements; the common requirements of castings, steel and alloy for general industrial use; and the titanium-stabilized carbon steel forgings, ferritic ductile iron castings suitable for low-temperature service, structural quality steels and hot rolled products for structural steels. During this interactive course, participants will learn the flat products made of steels and steel forgings for pressure purposes; the aluminum-alloy sand castings, composition bronze or ounce metal castings, copper-silicon alloy, aluminum-alloy permanent mold castings, nickel-copper alloy, aluminum-bronze sand castings, copper-nickel-zinc alloy, etc.; the specifications for welding rods, electrodes and filler metals; the stress tables, physical properties tables and charts and tables for determining shell thickness of components under external pressure; the basis for establishing design stress intensity values, pressure charts and stress values; the guidelines on multiple marking of materials and standard units for use in equations; nominal composition designations for ASME code materials and the guidance for the use of U.S. customary and SI units in the ASME boiler and pressure vessel code; the guidelines for rounding minimum specified tensile and yield strength values, establish anchor points for tensile and yield strength trend curves.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies:

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable:

| Certificates | : | Only soft copy certificates will be issued |

| Training Materials | : | Only soft copy materials will be issued |

| Training Methodology | : | 80% theory, 20% practical |

| Training Program | : | 4 hours per day, from 09:30 to 13:30 |

RELATED COURSES

ME0615 : Operation, Maintenance & Troubleshooting of Pumps & Compressors

- Date: Jan 19 - Jan 23 / 3 Days

- Location: Dubai, UAE

- Course Details Register

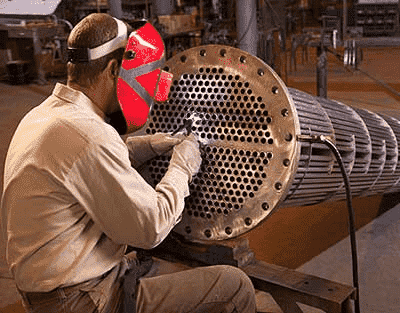

ME0062 : Heat Exchanger Operation, Maintenance & Repair

- Date: Jan 06 - Jan 10 / 3 Days

- Location: London, United Kingdom

- Course Details Register

ME0007 : Vapor Recovery Unit System

- Date: Dec 23 - Dec 26 / 3 Days

- Location: Al Khobar, KSA

- Course Details Register

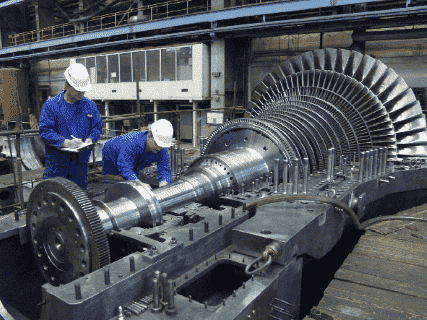

ME0015 : Centrifugal Compressor & Steam Turbine Design, Performance, Operation, Maintenance & Troubleshooting

- Date: Jan 05 - Jan 09 / 3 Days

- Location: Doha, Qatar

- Course Details Register