COURSE OVERVIEW

FACILITY INTEGRITY, INSPECTION, METALLURGY & CORROSION ENGINEERING

OVERVIEW

| COURSE TITLE | : | FE0433 : Welding Defects Analysis |

| COURSE DATE | : | Mar 03 - Mar 07 2024 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Mohamed Kader (FE) Days |

| VENUE | : | Doha, Qatar |

| COURSE FEE | : | $ 6000 |

| Request For Course Outline | ||

OTHER SCHEDULED DATES

| Date | : | Jul 07 - Jul 11 (5 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 6000 | Course Info |

| Date | : | Nov 10 - Nov 14 (5 Days) | Location | : | Doha, Qatar | Classroom Fee (US$) | : | $ 6000 | Course Info |

Course Description

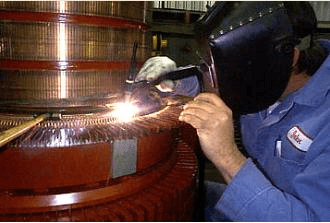

This practical and highly-interactive course includes practical sessions and exercises where participants carryout welding inspection. Theory learnt in the class will be applied using our state-of-the-art simulators. This course is designed to provide participants with an up-to-date overview on welding defects analysis. It covers the identification of various welding imperfections and defects; the relevant welding technology related to visual inspection, documentation in welding and code and standards related to inspection requirements; the proper inspection of parent materials and consumables; the visual inspection of welds; the reporting and assessing with specified acceptance criteria; the factors which influence the quality of fusion welds in steels; and the characteristics of commonly used welding process in relation to quality control and specifications of drawing instructions and symbols. The course will further discuss the validity of a welding procedure; the origin of weld defects; the features of a fracture surface; the detailed reports plan, the use of skilled inspectors and NDT personnel; the various types of weld defects and how it is expected to appear on a radiographic image and what causes them; the gas pour, linear porosity and lack of fusion; and the various types of cracks and weld repair methods. link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

FE0160 : Pipeline and Piping Design, Installation, Operation, Inspection, Testing, Maintenance, Repair, FFS, Pigging, Integrity & Rehabilitation (ASME B31 & API 579 Standards)

- Date : May 13 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register

FE0985 : Thermal Infrared Testing ASNT Level-1 Training & Certification (ASNT, SNT-TC-1A)

- Date : May 13 -May 17 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

FE0930 : API 577: Welding Inspection and Metallurgy (API Exam Preparation Training)

- Date : Jun 09 -Jun 13 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

FE0860 : AWS Certified Welding Inspector (CWI)

- Date : May 12 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register