COURSE OVERVIEW

FACILITY INTEGRITY, INSPECTION, METALLURGY & CORROSION ENGINEERING

OVERVIEW

| COURSE TITLE | : | FE0160 : Pipeline and Piping Design, Installation, Operation, Inspection, Testing, Maintenance, Repair, FFS, Pigging, Integrity & Rehabilitation (ASME B31 & API 579 Standards) |

| COURSE DATE | : | May 13 - May 16 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Marian Copilet Days |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 4500 |

| Register For Course | ||

OTHER SCHEDULED DATES

| Date | : | Jan 14 - Jan 18 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Mar 03 - Mar 07 (5 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 6000 | Course Info |

| Date | : | Aug 05 - Aug 08 (4 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Nov 11 - Nov 14 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

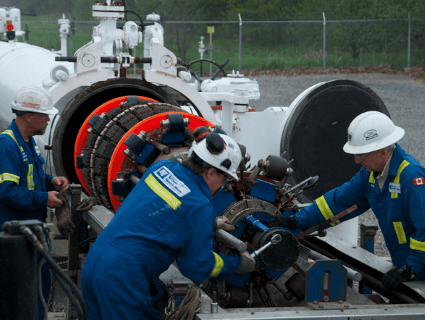

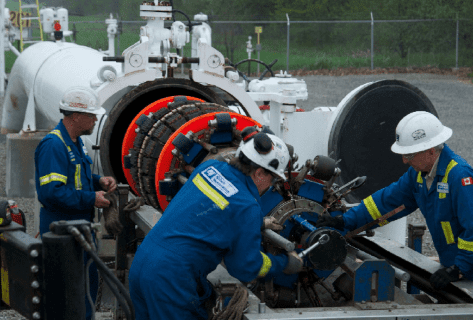

This practical highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. This course is designed to provide delegates with a detailed and up-to-date overview of Pipeline and Piping Inspection, Maintenance and Repair. Participants will be introduced to the technical basis of the ASME and API integrity rules, and their application to case studies and exercises. The participants will be able to recognize causes of degradation in-service, whether mechanically induced (pressure, vibration, fatigue, pressure transients, external damage) or due to corrosion (wall thinning, pitting, cracking), and apply integrity analysis techniques to make run-or-repair decisions. The participants will review inspection techniques, from the most common (PT, MT, UT, RT, MFL pigs) to most recent (AE, PED, UT pigs and multi pigs), and the implementation of integrity management programs, periodic inspections and evaluation of results. During this interactive course, participants will review the various repair techniques, their advantages and shortcomings, and the logic to be followed in making repair decisions and selecting the applicable repair

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

FE0433 : Welding Defects Analysis

- Date : Jan 26 -Jan 30 / 3 Days

- Location : Dubai, UAE

- Course Details Register

FE0985 : Thermal Infrared Testing ASNT Level-1 Training & Certification (ASNT, SNT-TC-1A)

- Date : May 12 -May 16 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register

FE0200 : Pipeline Pigging - Technical & Operational Aspects

- Date : May 20 -May 23 / 3 Days

- Location : Istanbul, Turkey

- Course Details Register

FE0048 : Welding and Cutting

- Date : May 19 -May 23 / 3 Days

- Location : Dubai, UAE

- Course Details Register