COURSE OVERVIEW

MECHANICAL ENGINEERING

OVERVIEW

| COURSE TITLE | : | ME0062 : Heat Exchanger Operation, Maintenance & Repair |

| COURSE DATE | : | Mar 03 - Mar 07 2024 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Saleh Aich Days |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 5500 |

| Request For Course Outline | ||

OTHER SCHEDULED DATES

| Date | : | Apr 21 - Apr 25 (5 Days) | Location | : | Doha, Qatar | Classroom Fee (US$) | : | $ 6000 | Course Info |

| Date | : | Jun 02 - Jun 06 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 5500 | Course Info |

| Date | : | Sep 01 - Sep 05 (5 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 6000 | Course Info |

Course Description

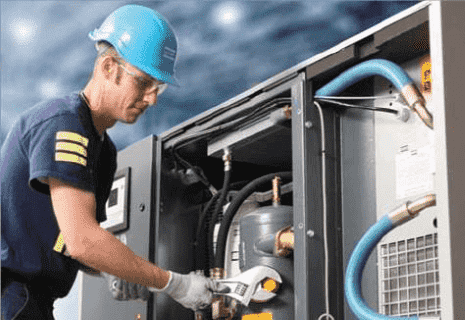

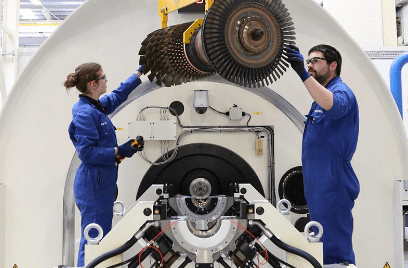

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. The design, performance and operation of modern heat exchangers require an understanding of the principles of heat transfer and fluid flow, coupled with access to numerically based techniques and supporting data. This course will review heat transfer fundamentals as applied to tubular and plate devices. Included will be sessions on the practical aspects of shell and tube heat exchanger design with ASME and TEMA codes. Upon completion of this course, delegates will gain an understanding of the basic principles of heat transfer and fluid flow and their application to the design, operation and maintenance of shell and tube heat exchangers as well as compact and air cooled heat exchangers. Participants will gain an understanding of TEMA and ASME codes and learn how to numerically analyze the different heat exchanger configurations. Attention will be paid to the recognition and solving of a wide variety of industrial problems, taking existing case studies.The course will also address the ways in which systematic techniques of inspection and maintenance (including Fouling Control) can alleviate major problem areas. Further, the course will explain the Energy Balance in Heat Exchangers and discuss the new technologies of Heat Transfer and heat exchanger within the industry. There will be troubleshooting workshops devoted to the discussion of regularly occurring heat exchanger problems, performance assessment and methods to improve the overall thermal efficiencies of these devices. The course will also cover current methods of inspection and maintenance. link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

ME0630 : The Layout of Piping Systems & Process Equipment

- Date : Dec 10 -Dec 14 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register

ME0976 : Screw Compressor Theory and Troubleshooting

- Date : May 13 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register

ME0398 : Pumps, Compressors, Turbines & Troubleshooting

- Date : May 13 -May 16 / 3 Days

- Location : Doha, Qatar

- Course Details Register

ME0562 : Pump Selection, Installation, Performance & Control

- Date : May 13 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register