COURSE OVERVIEW

SAFETY, HEALTH & ENVIRONMENTAL ENGINEERING & MANAGEMENT

OVERVIEW

| COURSE TITLE | : | HE0400 : Fundamentals of Process Safety & Loss Prevention |

| COURSE DATE | : | Dec 23 - Dec 26 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. Raymond Tegman Days |

| VENUE | : | Abu Dhabi, UAE |

| COURSE FEE | : | $ 4500 |

| Register For Course | ||

OTHER SCHEDULED DATES

| Date | : | May 13 - May 16 (4 Days) | Location | : | Istanbul, Turkey | Classroom Fee (US$) | : | $ 5000 | Course Info |

| Date | : | Sep 02 - Sep 05 (4 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

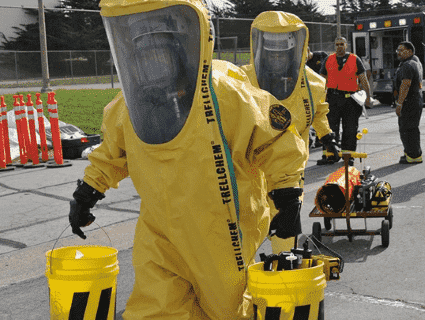

This practical and highly-interactive course includes real-life case studies and exercises where participants will be engaged in a series of interactive small groups and class workshops. Major incidents have been occurring around the world for as long as hazardous materials have been processed. Loss prevention is not only concerned with incidents that cause injury to people. It covers all forms of loss, including damage to the environment and property and interruption to production caused by major failures of a plant, even when there is no injury to people or damage to the surroundings.The escape of toxic methyl isocyanate vapour from the Union Carbide India Limited plant at Bhopal in India on December 1984 was the most serious chemical plant incident in history, causing thousands of deaths and many tens of thousands of severe injuries, many of them causing permanent incapacity. This and the explosion at the Phillips Petroleum polyethylene plant at Pasadena on 23 October 1989, which killed 23 people and injured hundreds more, alerted management and governments to the need for much more than traditional occupational safety and health programs to provide safety for those working in, or living around, process plants. However, this was not new knowledge. Major incidents have been occurring around the world for as long as hazardous materials have been processed.Loss prevention is not only concerned with incidents that cause injury to people. It covers all forms of loss, including damage to the environment and property, and interruption to production caused by major failures of a plant, even when there is no injury to people or damage to the surroundings. Avoidance or minimization of the risks of all these types of incident is embraced by the field of process-plant risk and reliability management. There are many reasons why organizations may be concerned with managing their risks. These range from avoidance of injury or the cost of replacing damaged equipment, to such matters as maintaining a good public image or avoiding legal claims or prosecution of senior managers for negligence.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

HE1526 : Technical Integrity Verification (TIV)

- Date : May 13 -May 16 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

HE1054 : Hazardous Materials Specialist: Hazmat Level IV (OSHA 29 CFR 1910.120 and NFPA 472)

- Date : May 12 -May 16 / 3 Days

- Location : Doha, Qatar

- Course Details Register

HE0758(KN1) : Certified Confined Space & Rope Rescue in Accordance with NFPA 1670 & 1006

- Date : May 13 -May 17 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

HE0793 : Oil Spill Management & Response (IMO OPRC Level 1 & 3)

- Date : May 12 -May 16 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register