COURSE OVERVIEW

FACILITY INTEGRITY, INSPECTION, METALLURGY & CORROSION ENGINEERING

OVERVIEW

| COURSE TITLE | : | FE0191 : Essential PIMS (Pipeline Integrity Management System) |

| COURSE DATE | : | Dec 09 - Dec 12 2024 |

| DURATION | : | 4 Days |

| INSTRUCTOR | : | Mr. John Dickerson Days |

| VENUE | : | Abu Dhabi, UAE |

| COURSE FEE | : | $ 4500 |

| Register For Course Outline | ||

OTHER SCHEDULED DATES

| Date | : | May 13 - May 16 (4 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 4500 | Course Info |

| Date | : | Aug 12 - Aug 15 (4 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 4500 | Course Info |

Course Description

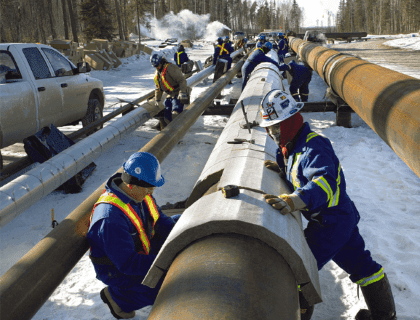

This practical and highly-interactive course includes practical sessions and exercises. Theory learnt will be applied using our state-of-the-art simulators. Pipeline Integrity Management is the process of managing pipeline operational risk and mitigating it effectively to ensure pipeline assets are maintained in safe and reliable condition. Pipelines generally constitute a single point failure for any facility which can often result in serious safety, environmental and business consequences once loss of containment has occurred. By monitoring the condition of the pipeline, the likelihood of an unplanned failure/shutdown of the pipeline can be prevented. Understanding the condition of the pipeline can also help to improve the planning of pipeline maintenance and inspection activities by identifying key activities in advance to allow the appropriate budgets to be implemented and reduce the amount of spending associated with unplanned activities. The course will provide participants the best practices on how to manage gathered data from various inspection techniques and apply them in modelling the potential failures. It will also teach attendees on how to optimize the inspection and maintenance resources to develop a comprehensive integrity management program covering both pipelines and their associated facilities. The necessary elements of such a program are described in detail with examples of typical program content including an overarching view of where detailed risk analysis and defect assessment fits in the program. Finally, the course will review the various repair techniques, their advantages and shortcomings and the logic to be followed in making repair decisions and selecting the applicable repair. In addition, pressure testing will be studied, including an exercise based on an actual hydrostatic pressure test. link to course overview PDF

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

FE0190 : Pipeline Inspection, Testing & Integrity Assessment: Defect Assessment in Pipelines (Practical Aspects)

- Date : May 20 -May 23 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register

FE0751 : Magnetic Particle Testing Level II Training & Certification (ASNT, SNT-TC-1A)

- Date : May 13 -May 14 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register

FE0759 : Visual Testing Level I Training & Certification (ASNT, SNT-TC-1A)

- Date : May 20 -May 21 / 3 Days

- Location : Dubai, UAE

- Course Details Register

FE0738 : Alternating Current Fiield Measurement (ACFM) Training & Certification Level 2 (ASNT, SNT-TC-1A)

- Date : May 19 -May 23 / 3 Days

- Location : Doha, Qatar

- Course Details Register