COURSE OVERVIEW

FACILITY INTEGRITY, INSPECTION, METALLURGY & CORROSION ENGINEERING

OVERVIEW

| COURSE TITLE | : | FE0771 : Ultrasonic Testing Level-II Training & Certification (ASNT, SNT-TC-1A) |

| COURSE DATE | : | Jul 21 - Jul 25 2024 |

| DURATION | : | 5 Days |

| INSTRUCTOR | : | Mr. Luis Lopez Days |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 6000 |

| Register For Course | ||

OTHER SCHEDULED DATES

| Date | : | Apr 28 - May 02 (5 Days) | Location | : | Doha, Qatar | Classroom Fee (US$) | : | $ 6000 | Course Info |

| Date | : | Oct 07 - Oct 11 (5 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 6000 | Course Info |

Course Description

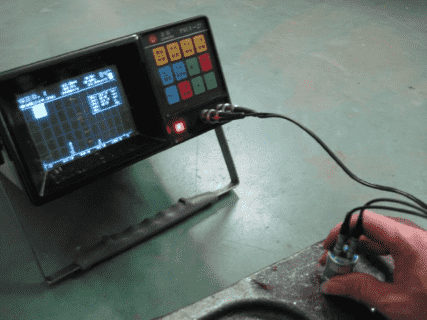

This practical and highly-interactive course includes various practical sessions and exercises. Theory learnt will be applied using our state-of-the-art equipment. This course will provide participants the theory lectures and practical training with a preliminary understanding of Ultrasonic Testing (UT) as per the ASNT Recommended Practice No. SNT-TC-1A for Personnel Qualification and Certification in Nondestructive Testing. Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization, and much more. Although there are a number of technologies employing ultrasound, the simplest explanation of what happens in this method is that sound energy is introduced via a transducer and propagates through the materials in the form of waves. When there is a discontinuity (such as a crack) in the wave path, part of the energy will be reflected back from the flaw surface. The reflected wave signal is transformed into an electrical signal by the transducer and is displayed or recorded in a variety of ways. Both surface and subsurface defects can be detected making ultrasonics a volumetric testing method. Applications vary in complexity from very small, hand-held manual units to very large, sophisticated automated systems. This method is used to inspect a variety of product forms including castings, forgings, and weldments. The structural steel, automotive, petrochemical, power generation, and aerospace industries are a few examples that utilize ultrasonic inspection.This course provides a review of basic ultrasonic theory, evaluation of weldments, innovative techniques to detect and evaluate discontinuities, equipment and advanced calibration methods. Sample Questions for general examinations are presented in the separate question booklets that can be obtained from ASNT International Service Center. Participants will further demonstrate familiarity with and ability to operate the necessary equipment for UT, record and analyse the resultant information to the degree required as well as test flawed specimen and component and analyse the results of NDT as part of the practical training.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

FE0191 : Essential PIMS (Pipeline Integrity Management System)

- Date : May 13 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register

FE0630 : Material Certification Management

- Date : May 12 -May 16 / 3 Days

- Location : Istanbul, Turkey

- Course Details Register

FE0890 : Technical Integrity & Engineered Safety in Process Plant

- Date : May 19 -May 23 / 3 Days

- Location : Doha, Qatar

- Course Details Register

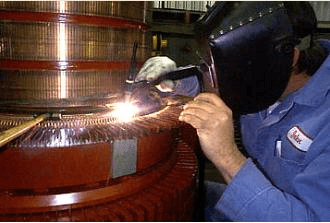

FE0860 : AWS Certified Welding Inspector (CWI)

- Date : May 12 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register