COURSE OVERVIEW

FACILITY INTEGRITY, INSPECTION, METALLURGY & CORROSION ENGINEERING

OVERVIEW

| COURSE TITLE | : | FE0670-10D : API 510: Pressure Vessel Inspector (API Exam Preparation Training) |

| COURSE DATE | : | Apr 14 - Apr 25 2024 |

| DURATION | : | 12 Days |

| INSTRUCTOR | : | Mr. Mohamed Kader (FE) Days |

| VENUE | : | Dubai, UAE |

| COURSE FEE | : | $ 8500 |

| Request For Course | ||

OTHER SCHEDULED DATES

| Date | : | Feb 25 - Feb 29 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 8500 | Course Info |

| Date | : | Mar 03 - Mar 07 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 8500 | Course Info |

| Date | : | Jul 08 - Jul 19 (12 Days) | Location | : | Abu Dhabi, UAE | Classroom Fee (US$) | : | $ 8500 | Course Info |

| Date | : | Sep 01 - Sep 05 (5 Days) | Location | : | Dubai, UAE | Classroom Fee (US$) | : | $ 7500 | Course Info |

| Date | : | Oct 06 - Oct 17 (12 Days) | Location | : | Al Khobar, KSA | Classroom Fee (US$) | : | $ 8500 | Course Info |

Course Description

This practical and highly-interactive course includes practical sessions and exercises where participants carryout welding inspection. Theory learnt in the class will be applied using our state-of-the-art simulators. This course is designed to train individuals who are interested in obtaining the API 510 Pressure Vessel Inspector Certification, as well as those who are seeking a better understanding of ASME Section VIII and IX code requirements. Included with the course is a pre-study guide and student classroom workbook. The student receives instruction regarding how to take the test, as well as insight into the intricacies of "real world" situations. Daily tests are designed to gauge students? proficiency and understanding of the material. The course covers head and shell calculations, hydrostatic test pressure calculations, reinforcement calculations, shell external pressure calculations, impact test requirements and determination, development and review of welding documentation and NDE requirement. Haward Technology is proud of its 90% pass rate on all our API sponsored courses.

TRAINING METHODOLOGY

This interactive training course includes the following training methodologies as a percentage of the total tuition hours

LecturesWorkshops & Work Presentations

Case Studies & Practical Exercises

Videos, Software & Simulators

In an unlikely event, the course instructor may modify the above training methodology before or during the course for technical reasons.

VIRTUAL TRAINING (IF APPLICABLE)

If this course is delivered online as a Virtual Training, the following limitations will be applicable

| Certificates | : | Only soft copy certificates will be issued to participants through Haward’s Portal. This includes Wallet Card Certificates if applicable |

| Training Materials | : | Only soft copy Training Materials (PDF format) will be issued to participant through the Virtual Training Platform |

| Training Methodology | : | 80% of the program will be theory and 20% will be practical sessions, exercises, case studies, simulators or videos |

| Training Program | : | The training will be for 4 hours per day starting at 09:30 and ending at 13:30 |

| H-STK Smart Training Kit | : | Not Applicable |

| Hands-on Practical Workshops | : | Not Applicable |

| Site Visit | : | Not Applicable |

| Simulators | : | Only software simulators will be used in the virtual courses. Hardware simulators are not applicable and will not be used in Virtual Training |

RELATED COURSES

FE0985 : Thermal Infrared Testing ASNT Level-1 Training & Certification (ASNT, SNT-TC-1A)

- Date : May 12 -May 16 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register

FE0989 : Infrared and Thermal testing Method (IR) II

- Date : May 12 -May 16 / 3 Days

- Location : Dubai, UAE

- Course Details Register

FE0320 : Metallurgy, Corrosion and Prevention of Failures: Material Selection and Properties

- Date : May 13 -May 16 / 3 Days

- Location : Abu Dhabi, UAE

- Course Details Register

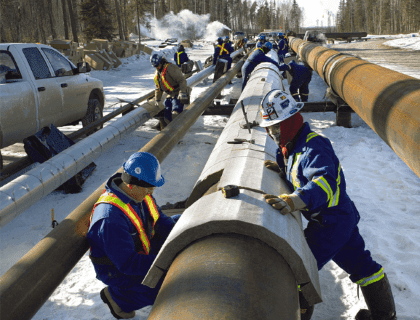

FE0190 : Pipeline Inspection, Testing & Integrity Assessment: Defect Assessment in Pipelines (Practical Aspects)

- Date : May 20 -May 23 / 3 Days

- Location : Al Khobar, KSA

- Course Details Register